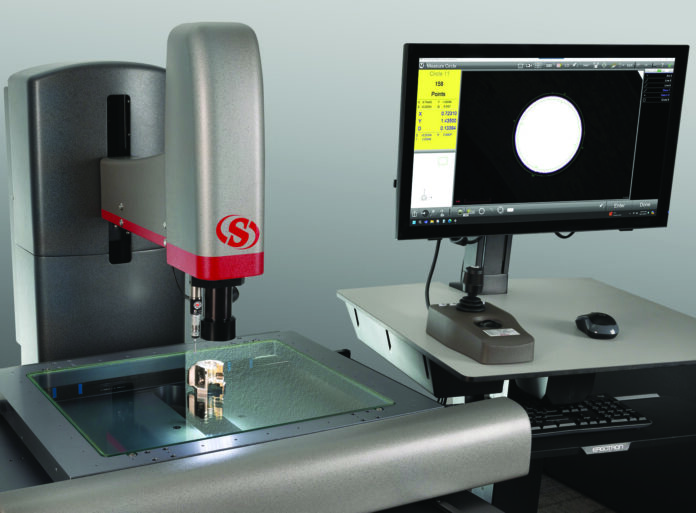

The L.S. Starrett Co., a leading global manufacturer of metrology systems, precision measuring tools and gages and more, has expanded its AVR Vision Metrology Line with the introduction of the AVR400 CNC Vision System, the largest benchtop platform to date from Starrett with stage travel that is twice the speed of previous Starrett AVR models. The stage travel is 15.8″x 11.8″x 7.9″ (400mm x 300mm x200mm) in the X-Y-Z axes with a speed of up to 120mm/ sec.

“We are very pleased to offer customers a new, faster vision system capable of measuring a broader range of larger part sizes, as well as providing the ability to put more parts on the stage at one time,” said Mr. Mark Arenal, General Manager, The L.S. Starrett Company – Metrology Division. “Users will reduce inspection and measurement time, while maintaining accuracy.”

The Starrett AVR400 offers full CNC capabilities including X-Y-Z positioning and comprehensive zoom and telecentric lens options. Users can also choose to use motorized manual positioning via a pendant with a joystick and track ball. Equipped with the M3 software package from MetLogix™, a traditional mouse as well as a touchscreen monitor make user interaction easy and intuitive.

Auto part recognition enables creating a part measurement program that comprises the desired features of a part for inspection, which can automatically be saved in the system or to a network. Programmable light output options can be built into the program as defined steps, including being called up as the part recognition program initiates. Once the program is created, placing that part within the camera’s field-of-view allows for the saved program to initiate and run the inspection. A Renishaw Touch Probe may also be utilized for quick acquisition of discreet points along a part’s profile as well as Z-axis measurements.

For high stability, the AVR400 features a granite base. An extensive line of accessories is available including a modular system workstation on rolling caster wheels, providing convenient repositioning on the shop floor and in QC labs. The AVR400 Vision Metrology System is Made in the U.S.A.

About The L.S. Starrett Company

Founded in 1880 and headquartered in Athol, MA U.S.A., The L.S. Starrett Company is a leading global manufacturer of precision measuring tools and gages, optical comparators and vision systems and force and hardness testing solutions. Starrett also manufactures laser measurement systems, custom engineered granite solutions, custom gaging, band saw blades, power tool accessories, saw blades, workshop tools and jobsite tools. The Starrett brand is recognized throughout the world for exceptional quality and precision. Skilled personnel, superior products, manufacturing expertise, innovation and excellent service and support have earned Starrett its reputation as the “World’s Greatest Toolmakers”. Starrett has over 1,400 employees worldwide. The company has five manufacturing locations in the U.S.A., including facilities in Massachusetts, Georgia, Ohio, Minnesota, and California. Starrett also has three international manufacturing facilities. Plants are located in Brazil, Scotland and China, in addition to distribution centers and offices located worldwide.