In a recent interview with Industrial Machinery Digest, Jim Fields, Vice President of Techni WaterJet, shared insights into the company’s commitment to innovation, customer service, and the technological advancements that set them apart in the water jet fabrication market. With decades of experience in the industry, Fields provides a comprehensive overview of Techni WaterJet’s evolution, unique features, and future prospects.

A History of Excellence

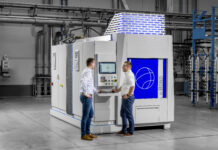

Techni WaterJet, born in Australia in 1989, has been a prominent player in the water jet industry for over three decades. The company expanded to the United States in 2005, rapidly growing its presence and reputation. Fields, who has been in the water jet industry since 1993, emphasizes the high-end quality and intelligence of Techni’s products. “We offer a high-end quality product with the most intelligence on the market,” he notes, highlighting the company’s focus on innovation and customer-centric design.

Customer Service: A Core Value

Customer service is at the heart of Techni WaterJet’s operations. Fields underscores the importance of proactive support, stating, “Customer service is paramount. It’s paramount to Techni, but even in our own lives, what is the most frustrating thing that we experience today is poor customer service.” Techni WaterJet ensures ease of operation and maintenance for their customers, aiming to minimize downtime and maximize productivity.

Proactivity in customer service is a key differentiator for Techni WaterJet. Their systems are designed to be unmanned, allowing for lights-out operation. This requires comprehensive monitoring of the machine’s parameters, including heat, torque, amp draw, and stroke rate. By predicting maintenance needs, Techni WaterJet helps customers avoid unexpected downtime. “Our system is designed to be unmanned… We use the term predictive when it comes to the tools on the machine,” Fields explains.

TechConnect: Advanced Monitoring and Control

TechConnect: Advanced Monitoring and Control

One of Techni WaterJet’s standout innovations is the TechConnect app. This intuitive tool, compatible with smart devices, allows users to monitor machine parameters in real-time. “It’s a very advanced tool,” Fields says. “It gives us a great deal of confidence to be unmanned. Set it and forget it.” The app alerts users to potential issues, enabling timely interventions and maintaining optimal performance.

The TechConnect app offers significant benefits for operators, maintenance personnel, and operations managers. It monitors critical indicators such as water pressure, oil flow rate, and temperatures, providing a comprehensive overview of the machine’s status. Fields adds, “It’s powerful across the spectrum. The ultimate is having us do the monitoring as well.”

Innovation at the Core

Techni WaterJet’s commitment to innovation is evident in their development of the electric servo pump, a patented technology that offers greater efficiency than traditional hydraulic intensifiers. “We hold the patent. We were the first to the market with an electric servo pump,” Fields states proudly. This technology, initially inspired by NASA’s use of electric actuators, exemplifies Techni WaterJet’s problem-solving approach and dedication to advancing the industry.

Another notable innovation is the abrasive transfer pump, which allows for continuous loading of the hopper without interrupting the cutting process. This non-pressurized vessel eliminates the need for depressurizing, streamlining operations and reducing downtime. Fields emphasizes, “We’ve always been driven by efficiency. How can we do it better, cheaper, with more reliability?”

Versatility and Efficiency

Versatility and Efficiency

Techni WaterJet’s machines stand out for their versatility and efficiency. They can cut a wide range of materials, from titanium and composites to glass and stone, without imparting heat or distorting the metal. “The versatility of it… It can cut anything from titanium to composite to plastic,” Fields elaborates. This cold-cutting process preserves the integrity of the parent metal, eliminating the need for secondary processing and allowing for immediate assembly or welding.

Comprehensive Support Programs

Techni WaterJet’s commitment to customer success extends beyond the sale. Their goal is to make customers independent through extensive training on maintenance, servicing, and software. For those who prefer not to handle maintenance themselves, Techni offers various levels of service contracts, from periodic check-ins to full monitoring and maintenance. Fields explains, “We want to be the same person after the sale as well. Promise less, deliver more.”

The true measure of success for Techni WaterJet’s customer service is repeat business. “The ultimate outcome and measure of whether we’re doing our job is the purchase of that second machine or a good testimonial,” Fields asserts. This focus on long-term relationships and customer satisfaction drives the company’s approach to service and support.

Personal Values and Professional Integrity

On a personal note, Fields emphasizes the importance of honesty and integrity in his work. “The ultimate, I guess, being honest and integrity, that’s key and foremost for me,” he shares. Fields believes in staying calm in chaotic situations and addressing customer concerns with a level-headed approach. This philosophy has guided his career and contributed to Techni WaterJet’s reputation for reliable, customer-focused service.

Looking Ahead

Techni WaterJet continues to lead the industry with cutting-edge technology and exceptional customer service. For those interested in learning more about their innovative products and services, Fields encourages visiting their website or reaching out directly. “We’re always welcome to answer your questions and help out in any way we can,” he assures.

Techni WaterJet exemplifies the fusion of innovation and customer service, setting new standards in the water jet fabrication market. With a commitment to efficiency, reliability, and proactive support, they are poised to remain industry leaders for years to come.