ModuleWorks announces the 2022.12 release of its digital manufacturing software components with new and enhanced features across the company’s entire CAD/CAM/CNC portfolio, including a new deburring preview, new cycles for rotary and turn milling, multi-regions for fused deposition modeling, and simulation and post processing for U-Axis turning operations.

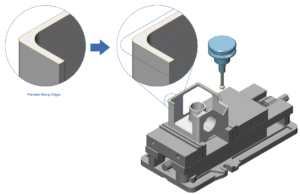

Deburring: preview of sharp edges

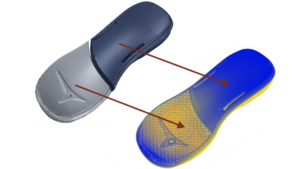

Preview of Deburring Curves

For multi-axis subtractive machining, there is a new option to preview the automatically detected deburr edges before calculating the toolpath. Users can also include/exclude drive curves in/from the toolpath calculation to speed up programming.

Rotary machining and turn milling

Floor Finishing for Rotary Machining

The rotary machining component now offers a floor finishing cycle to complete the ModuleWorks basic finishing portfolio of wall and floor finishing.

In addition, users can now use the cusp height to adjust the stepover on rotary and turn milling operations. It works for all supported tools and incorporates the axis offset to eliminate complex manual calculations.

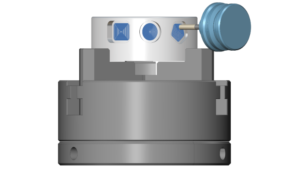

Machine and cutting simulation

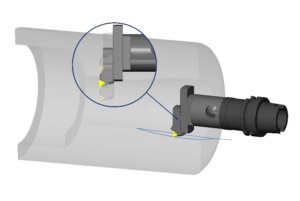

Simulation of U-Axis Turning

The ModuleWorks Machine Simulation now supports U-axis turning where the part is static and the turning tool is mounted on the spindle and rotates around the workpiece. The Machine Simulation now also includes flexible machine components such as cables or elastic bellows that are used as machine covers. These components are attached to a fixed point and connect to a movable component.

For the Cutting Simulation, enhanced triangulation algorithms accelerate the generation of the simulation model. This also speeds up mesh export which significantly enhances the performance of stock management where the stock is exported after each operation.

Multi-regions for Fused Deposition Modeling

Assign different properties to different deposition regions

With this new feature for fused deposition modeling, users can divide a workpiece into separate regions and apply different settings to the layers, walls and infills in each region. This adds manufacturing versatility and enables operators to enhance the quality of the final product, for example by applying different infill densities to different regions to compensate for forces/pressures.

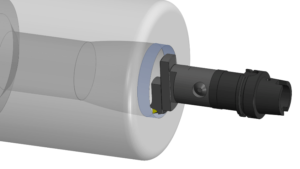

Post processing for U-Axis turning systems

U-axis / facing head / facing slide kinematics

The ModuleWorks MultiXPost post processor now supports U-Axis turning systems, also known as facing head or facing slide kinematics. The input is a turning toolpath. Markers on the toolpath indicate when to engage the special translation axis. This creates an operation where the machine first travels above the workpiece and then, using the U-Axis instead of the other translation axis, cuts the desired shape in turning mode.

About ModuleWorks

ModuleWorks is the leading software component provider for the digital manufacturing industry. With over 200 employees and 1000 person-years of software development, ModuleWorks’ expertise in toolpath creation and simulation is recognized throughout the industry and its software components are already optimizing the performance and quality of over 500,000 installed seats of CAD/CAM and CNC software around the world. From standard products to exclusive development projects, ModuleWorks helps companies to bring their vision of Industry 4.0 to life. With its comprehensive portfolio of cutting-edge software components, ModuleWorks enables its customers to optimize their CAD/CAM solutions and connect to CNC/MTB systems to increase their competitiveness and help them Get There Faster.