Customers from Germany, the US and China have already invested in laser blanking lines from Schuler. Recently, Schuler received another order from the People’s Republic—this one by one of the largest Chinese steel producers for a plant in Tianjin, as well as an order from a customer in South Africa. Around 50 visitors took advantage of Schuler’s invitation to learn about the benefits offered by the technology during two days in Heßdorf, Germany. They also had a chance to look at the actual system that will be delivered to China.

South African automotive supplier VM Automotive is expected to begin producing blanks for the plant of a high-end German automaker in South Africa (among other jobs) on a Laser Blanking Line 2.18 in the fall of 2020. The newly established blanking operations will handle the full scope of material logistics for the car manufacturer, thereby increasing the value in South Africa. By investing in this highly flexible laser blanking line, VM Automotive was able to gain the upper hand over competitors that use conventional blanking systems. Additional logistics centers are planned for other auto manufacturers in South Africa.

In 2014, a high-end German automaker ordered one of two laser blanking lines for mass production, and the equipment began producing two years later. “Our customer no longer has any dies for these blanks,” noted Martin Liebel, who manages the Schuler site in Heßdorf, a town located in the vicinity of Nuremberg. A highly flexible laser beam now performs the work formerly handled by the dies. This laser beam makes it possible to alter the blanking shape at the push of a button, whereas altering a blanking die can take several months, not to mention the accompanying costs for storage and maintenance. And when the set up time is taken into consideration, the overall equipment effectiveness (OEE) climbs to 80% for the laser blanking line, compared to just 65% for conventional press blanking lines.

With the system’s DynamicFlow Technology, a laser blanking line is up to 70% as productive as a modern servo blanking line with a press. “Output actually significantly exceeded our expectations,” said Liebel, adding that it had been possible to regularly increase output by a few percentage points with the help of a number of smaller measures. A proven cleaning process ensures that the system produces high-quality blanks which are also spotless—an important requirement for critical body shell parts. The same German carmaker went on to order two additional high-tech lines in 2017.

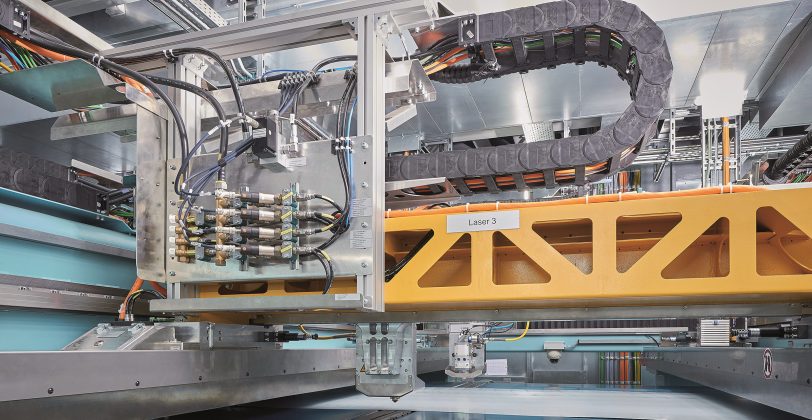

At roughly the same time, Schuler began developing a new concept featuring two laser heads instead of three. “We needed a basic machine that would also deliver solid, acceptable performance for the rest of the world,” said Liebel. The decision proved to be the right one, as evidenced by the orders for one Laser Blanking Line 2.18 each from China and South Africa this year. “The systems are becoming more and more dynamic, and the concept will win out in the end,” said a confident Liebel.

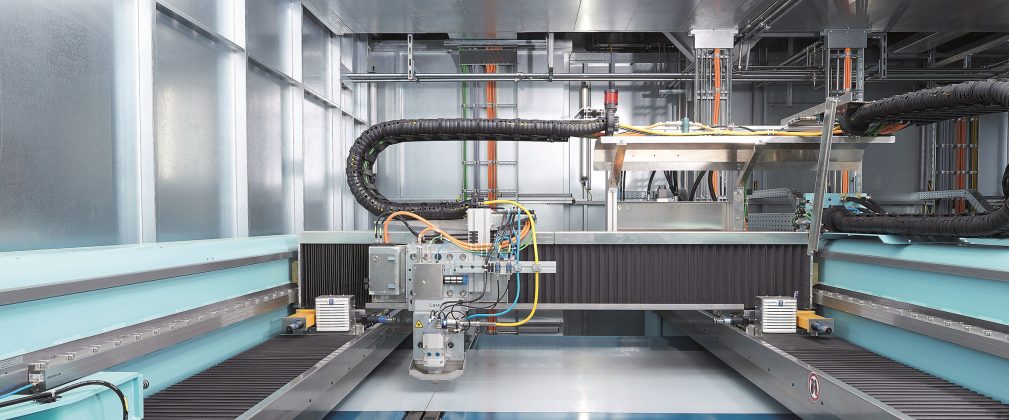

Distance Control between Laser Heads and Coil

One of the things that makes these systems so dynamic is the distance control for the lasers. This control maintains a distance of 0.7 to 0.9 mm from the continuously moving coil and, where necessary, corrects the distance within fractions of a second to ensure that any residual surface irregularities in the sheet metal do not damage the heads. Liebel explained, “This axis is critical to the line’s output. Each coil contains residual waves. If I’m looking to blank at a rate of 100 meters per minute, I need to be able to respond extremely dynamically.”

Larger surface irregularities are eliminated by the straightener. “The straightening result is a key ingredient to a stable process, especially for the laser blanking line,” added Regional Sales Manager Justine Fonteyne. “To make this happen, we use the ‘Check2Flat’ system, which adjusts the crowning on the straightener rollers.” Either the visualization system makes a recommendation based on the adjustment system, which the operator must then review, or the straightener itself can provide a fully automated control. “It’s important to remove as much of the tension from the material as possible so that the metal doesn’t pop up during blanking. These types of systems help to ensure process stability.”

Global Production Capacity Can Be Easily Used

According to Liebel, another increasingly important aspect for carmakers is the intelligent capacity utilization of production facilities across the globe. “But it’s difficult to make a product somewhere else on short notice if you’re using a press blanking line. To do so, our customers first have to move the die, prepare it for shipment and then send it off.” If a supplier is producing the blanks, the scrap chutes or something else may not fit. “With laser blanking lines in the production network, all I have to do is send a data set for the desired part and make sure that the coil material is available on-site. If the system has available capacity, production can start one or two hours later. It’s really a huge advantage.”

Fonteyne’s coworker Berthold Jüttner offered another example: “One of our customer’s plant managers had a problem with a blanking press and had asked another plant manager if he would be able to cut a few blanks for him on the latter’s laser blanking line. He then immediately sent the drawings and had the coils brought to the site. Blanking began the next day.”

High Surface Quality and Material Utilization

In addition to the newly achieved blank programming freedom, Jüttner saw another advantage in the line’s excellent dimensional accuracy, reproducibility and surface quality. “There are no burrs and the amount of cuttings is significantly less than in conventional blanking.” The so-called “angel’s hair” phenomenon is especially prevalent where blanks are cut from aluminum coils, and is also the reason why blanking presses regularly need to stop so that the dies can be cleaned. “This is no longer an issue with the laser blanking line.”

Laser blanking also makes it possible to support the material across its entire surface area. “We can nest the parts edge-to-edge on the coil and no longer need the 8 to 10 mm dividers required when using the blanking dies. For small cutouts, we can briefly open the belts and the scrap can drop into the scrap chute. On the new lines, the scrap and the usable parts are no longer separated using robots, but rather by an intelligent sorting system. This provides an additional boost in output.”

Laser Easily Handles High Strength Steel

The growing amount of high strength steels used in automobiles is increasingly pushing blanking presses closer and closer to their maximum mechanical loads, adds Liebel, who noted: “When it comes to yield strengths, there are no limits in laser blanking. We have performed many tests and high-strength steels are no problem.” As Jüttner added, “The laser doesn’t care at all what’s under it.”

According to Liebel,” The bundled beam of light darts across the metal coil at speeds of up to 100 meters per minute and a thickness between 0.7 and 2.5 mm.” Before the year 2000, it was only possible to achieve blanking speeds of 4 or 5 meters per minute using CO2 lasers. Then the fiber laser made its triumphant entrance and opened up the possibility of laser blanking for the first time. This development wouldn’t have been possible with conventional gas lasers.”

In addition, noise emissions are much lower than with blanking presses. “If sound protection is installed on the laser blanking line, you’ll have to look very carefully to see whether the line is running or not,” Jüttner commented. He added that a person can have a completely normal conversation, as long as a press isn’t running next to them. The investment cost is also significantly lower, since the laser line is not as tall and also does not require an elaborate press foundation. “That’s a huge cost factor,” concluded Jüttner. The loop for the material buffer is also routed above ground. However, the laser line’s energy requirements are comparable to those of a press blanking line.

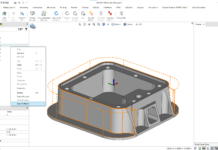

Software Makes Blank Programming Easier

Schuler has developed a software package, the LBL Studio, designed to greatly reduce the operator workload required to program the laser cutting movement. “All you have to do is upload the drawing data and the program will calculate the best-possible contours, the possible nesting options and the optimum level of laser utilization,” Fonteyne said as she listed the software’s benefits. “This means that users can already define the laser movement contours and configure the transitions offline. The binding output quantities can also be predicted. After that, the data can be transferred to the control system, and production can be run exactly as configured.”

About the Schuler Group

Schuler offers customer-specific cutting-edge technology in all areas of forming technology – from networked presses to press shop planning. In addition to presses, the product portfolio also includes automation and software solutions, dies, process know-how and service for the entire metalworking industry. Our customers include automobile manufacturers and automotive suppliers, as well as companies from the forging, household appliance and electronics industries. Presses from the Schuler Group mint coins for more than 180 countries. As a provider of innovative system solutions, we support our customers worldwide in the digital transformation of forming technology. In the 2018 fiscal year, Schuler generated sales of € 1 212 billion. Schuler AG, founded in 1839 at its headquarters in Göppingen (Germany), has approx. 6 600 employees at production sites in Europe, China and America as well as service companies in over 40 countries. The company is majority-owned by the Austrian ANDRITZ Group.

Schuler in Heßdorf was founded in 1962 as Hermann Schleicher GmbH, with the original headquarters in Erlangen, before joining the Schuler Group in 1990. The facility’s product portfolio includes automation solutions ranging from coil loading to end-of-line destacking. The most important areas it serves are the auto manufacturing, automotive supplier, and household appliance industries. The location employs approximately 350 people.