The software specialist CoreTechnologie has developed the 4D_Additive Manufacturing Software Suite. A particular highlight of the new software is the innovative texture module.

Revolutionary Component Design

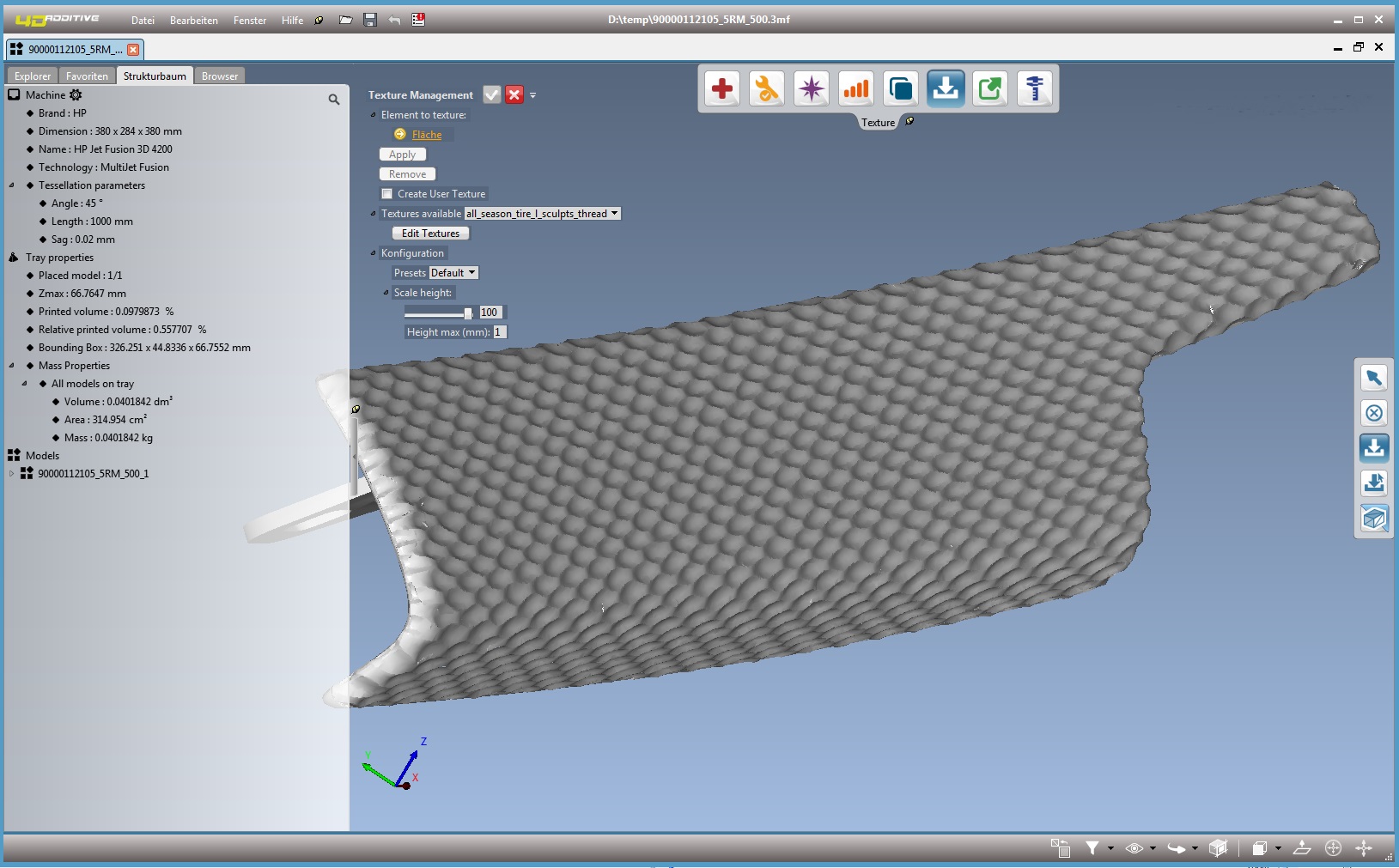

With the new texture module of 4D_Additive Manufacturing Software, developers and industrial designers are now accessing over 5,000 different surface structures. The combination of the software with precise B-Rep kernel and the high-resolution HP

Jet-Fusion process allows the additive production of very fine, completely new surfaces, which will find application in the future for individualized decorative trim in vehicles and plastic design products.

Flexible customization and new component designs are an important innovation advantage in a highly competitive buyer market. For users, 4D_Additive makes it easy to define textures on the CAD model, simply choosing the desired B-Rep areas and a matching texture from the database. Thereafter, the fineness and position of the structure can be visually adjusted on the component. A rendered, almost photorealistic representation of the model accelerates the work and allows an immediate assessment of the print result. The software automatically ensures distortion-free projection of the grain over surface boundaries. The graphical representation allows the assessment of the designed geometry and fuels the creative process in the design of new parts.

New Precision in Additive Manufacturing

The trend-setting tool reads CAD data from all common systems such as Catia, NX, SolidWorks, Creo, Inventor, STEP or JT with manufacturing information (PMI) and processes them as exact B-Rep geometry. The robust B-Rep geometry core of the software makes it possible to test, repair and prepare the original surfaces and solids of the exact 3D CAD Engineering Standard models.

In addition to the innovative texture module, the 4D_Additive Software Suite features healing and clean-up capabilities, automated part alignment, intelligent nesting capabilities with multi-processor calculation, an analysis tool for optimal part design, part optimization, and shell geometry and a partfinder as a search engine for 3D printing parts for the fully automatic classification of components on the basis of geometric properties of the CAD models.

About CoreTechnologie

Since its foundation in 1998, the software manufacturer CoreTechnologie with locations in Germany, France, USA, Japan and Great Britain has been led by the managing directors Dominique Arnault and Armin Brüning. With innovative products, the visionary company has consistently optimised its product portfolio and secured the technological leadership in the area of conversion software. Each year, CoreTechnologie invests more than 30 per cent of sales in the research and implementation of new technologies and has the most complete product range in this field.

In the focus of technology development is the product line of “3D Evolution” which guarantees efficient and lossless exchange of complex data structures between independent and heterogeneous CAX software solutions. With extremely powerful native interfaces for all leading CAD systems and for conversion of all common 3D formats, the software module ensures optimal interoperability of most various IT solutions.

Apart from providing visualisation and manufacturing data across most various systems, CoreTechnologie offers outstanding technologies for automatic data correction, feature-based conversion, geometry optimisation, quality control and long-time archiving as well as for visualisation of complex 3D models. The software components for software manufacturers of the most different CAX applications are the company’s second leg.

The customer portfolio of CoreTechnologie comprises more than 400 companies from the automotive, aerospace, engineering and consumer goods industry who are in many cases the quality leaders in their relevant segment.