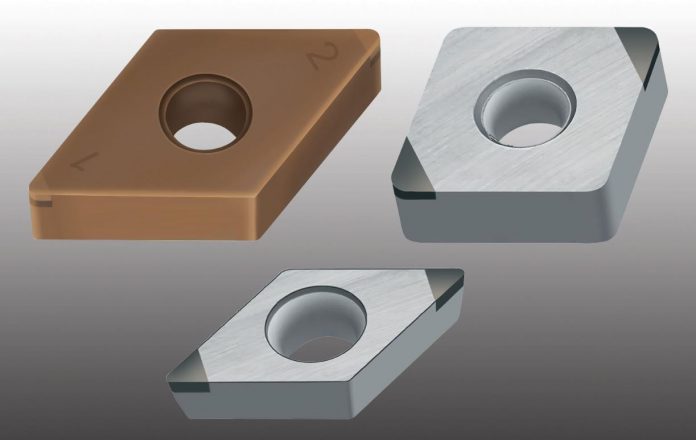

Walter has introduced new CBN grades for improved turning of hardened steel up to 65 HRC. These grades: WBH10C, WBH10, and WBH20, provide users with an array of benefits. High quality surface finish due to unique new wiper geometry (MW2) and long tool life with the new TiAlSiN coated CBN grade (WBH10C) are just some of these benefits. Inserts with laser etched chip breaker geometry TM-M2 are also available.

All inserts are ground for exceptional process reliability. These new grades are available in both positive and negative inserts and are suitable for both continuous and interrupted cuts.

Additionally, Walter has also introduced WBS10, a new CBN grade for finishing high-temperature superalloys in either continuous or interrupted cuts. Available in both positive and negative inserts, WBS10 features sharp “EM2” microgeometry and superfine grain with ceramic binder.

About Walter

Walter, a global leader in the metalworking industry for over 100 years, offers a wide range of precision tools for milling, turning, drilling and threading applications. The company helps customers in the aviation and aerospace industries, automotive, energy, and general industry improve process reliability and increase productivity. As an innovative partner capable of creating digital process solutions for optimal efficiency, Walter is pioneering Industry 4.0 throughout the machining industry. With Regional Headquarters in Waukesha, WI, Walter markets its competence brands Walter, Walter Titex, Walter Prototyp and Walter Multiply through a network of channel partners and field engineers across the USA, Canada, Mexico and Brazil.

Walter USA, LLC

N22 W23977 RidgeView Pkwy West | Suite 100

Waukesha, WI 53188

(800) 945-5554