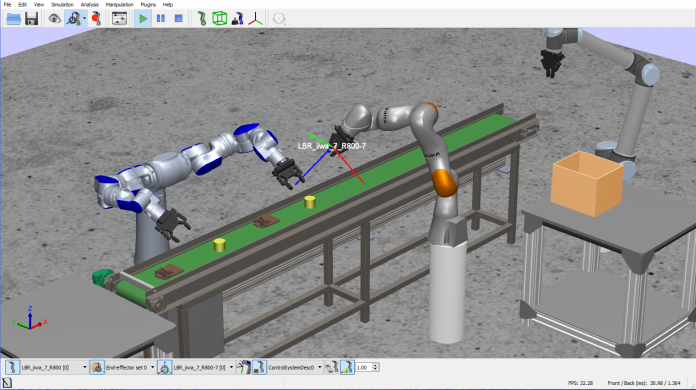

Energid has released Actin® 5, a significant update to its software development kit (SDK), which was showcased at the International Manufacturing Technology Show (IMTS) in September. The Actin toolkit is the industry’s only real-time adaptive motion control software, allowing robotic system developers to focus on the robot’s task rather than joint movement and paths. The Actin software responds in real time to sensory input and directs the robot on the most efficient path while avoiding collisions. The robot motion is updated dynamically without requiring reprogramming, even in dynamic, mission-critical environments.

Configurable robot controller framework

Actin 5 adds to the software’s powerful capabilities with a new robot controller development framework that is configurable through XML for application on a wide range of platforms, including real-time operating systems. The framework’s modular design and XML configuration allows system developers to embed Actin’s advanced kinematic control capabilities into existing robotic systems with minimal programming, or to more easily develop a completely new system from proof of concept through commercial deployment. In both cases, Actin can save months or years of development time over in-house programming and open source tools that can introduce security and support concerns.

“We continue to improve Actin, making it more powerful and easier to use,” said Neil Tardella, Energid CEO. “Traditionally, developers of robotic systems would have to program many intermediate waypoints to avoid collisions with the environment and would have to hand tune paths to avoid collisions, singularities and joint limits for process-related tasks. But not with Actin 5, which automatically finds optimal paths in real time. Developers can focus on the tool motion and let Actin find and optimize the robot’s joint motion.”

Easy-to-use scripting language and HMI development toolkit

Actin 5 also adds a new EcScript™ scripting language to make the toolkit easier to use and faster to learn. EcScript lets developers, even with no knowledge of advanced programming languages, create powerful motion commands with just a few lines of code. Software developers can still use C++ for advanced features if desired, using the Actin 5 SDK’s improved documentation for C++ APIs.

A new human-machine interface (HMI) toolkit in Actin 5 allows developers to create touchscreen- or teach-pendant-friendly user interfaces (UIs). The HMI toolkit is built on Qt QML for multi-platform UI development and provides simple access to Actin features through QML properties. Rendering and visualization tools are also accessible from within QML to provide a rich user experience. Reference designs are available for commonly required UI features such as robot jogging controls, work-cell rendering and contextual overlays.

“Actin 5 changes the game for robot systems developers, for both in-house automation teams at large manufacturers as well as entrepreneurs developing sophisticated robotics systems,” said Douglas Barker, Energid COO. “These developers know what they need the robot to do, but can miss market opportunities and budget targets while struggling to program the robot’s motion. Actin 5 gives any robotics developer the ability to incorporate adaptive, real-time motion control more quickly and easily.”

The Actin SDK can be used with any type of industrial or collaborative robot or complex articulated mechanism in any type of application, including those in the industrial, medical, Oil & Gas, agricultural, and aerospace domains.

See Energid in action here:

Bin Picking | External Tool Center Point (TCP) | Human-like Adaptive Motion

About Energid Technologies

Established in 2001 and headquartered in Cambridge, Massachusetts, United States, Energid Technologies develops advanced real-time motion control software for robotics. Energid’s general robot control and tasking framework, Actin®, is built to meet the rigorous requirements of industrial, commercial, collaborative, and consumer robotic systems. Energid licenses Actin as a cross-platform software toolkit and provides integration services to help its customers get to market quickly.

In 2018, Energid was acquired by Teradyne. Teradyne is the leading supplier of automated test equipment used to test semiconductors, wireless products, data storage, and complex electronic systems. Teradyne’s portfolio also encompasses Industrial Automation products, including collaborative robots, autonomous mobile robots and sensing and simulation software, used by global manufacturing and light industrial customers to improve quality and increase manufacturing efficiency. Energid continues operations under the same management and Energid’s headquarters, R&D, and engineering facilities remain in Massachusetts, USA.

Energid

213 Burlington Road, Suite 101

Bedford, MA 01730

P: 888-547-4100