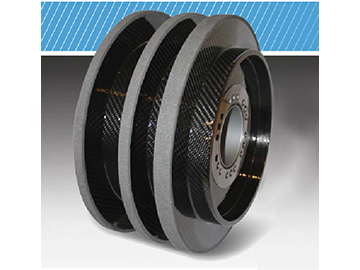

New Lightweight Norton CarbonForce Vitrified cBN Wheels Deliver Increased Operator Safety, Enhanced Performance and Superior Finished Parts

Saint-Gobain Abrasives, the world’s leading manufacturer and supplier of performance-engineered abrasives, has introduced CarbonForce, a new lightweight line of vitrified cBN wheels for OD grinding. With proprietary high-strength carbon fiber cores, CarbonForce wheels are 75% lighter than heavier steel-hubbed wheels and provide the safety and performance-enhancing benefits of a precision super-abrasive wheel.

With their lightweight carbon fiber core, CarbonForce wheels reduce labor costs and strain on the operator and often eliminate the need for a crane because they meet most safe lifting weight limits. The wheels exhibit high strength vs. centrifugal force and have been qualified to run at MOS of 31,496 fpm (160 m/s) for wheels with an OD >7.9” (200mm). In addition, the low thermal expansion of the carbon fiber increases safety and performance.

The perfect combination of a robust, thermally stable, lighter weight core with vibration dampening technologies and an advanced vitrified cBN bond system means CarbonForce wheels require less operator intervention to control part quality. This dynamic combination reduces dressing frequency, while increasing wheel life.

The new Norton wheels provide dramatically reduced cycle times by allowing the operator to mount four CarbonForce wheels vs. one steel rim wheel onto a four-phase cam shaft for simultaneous grinding of all four lobes in one operation. Cycle time, changeovers, dressing frequency and labor costs can all be reduced by up to 75% by changing out all four wheels.

The lightweight design of CarbonForce wheels extends bearing, spindle and overall machine life and reduces power draw and energy consumption for acceleration and deceleration in linear and rotary movement. All wheels are also equipped with a steel bushing to ensure long life of the wheel bore.

All Norton CarbonForce wheels are made-to- order with a maximum diameter of 1,000mm and a maximum width of 650mm. Large, complex wheel set designs are available with CarbonForce’s compact, lightweight core.

To learn more about the entire Norton Industrial product line, visit www.nortonindustrial.com

About Saint-Gobain Abrasives

Backed by its experience and its capacity to continuously innovate, Saint-Gobain, the world leader in the habitat and construction market, designs, manufactures and distributes high-performance and building materials providing innovative solutions to the challenges of growth, energy efficiency and environmental protection. With 2015 global sales of $44 billion, Saint-Gobain operates in 64 countries and has more than 180,000 employees. For the fourth year in a row, the Company has been ranked by Thomson Reuters as one of the Top 100 Global Innovators.

In the United States and Canada, Saint-Gobain has more than more than 150 locations and approximately 15,000 employees, with sales of approximately $5.7 billion in 2015. Saint-Gobain is the world leader in abrasives and the only international manufacturer to offer a full complement of abrasives products to customers worldwide.

Saint-Gobain’s Abrasives business employs nearly 11,000 people at 64 manufacturing facilities in 27 countries. In the United States and Canada, Saint-Gobain’s Abrasives business has more than 2,100 employees at eight manufacturing sites. For more than 30 years, Saint-Gobain Abrasives has supported the United States Luge Association by providing engineering expertise to improve the performance and speed of luge athletes and by donating its Norton® brand of abrasive products. Since 2009, Saint-Gobain has been the primary sponsor of the USA Luge team.

For more information about Saint-Gobain, visit www.saint-gobain.com and the twitter account @saintgobain or download the “Saint-Gobain Shareholder” application for tablet and smartphone.