Mazak Booth Draws Thousands at IMTS 2016

Company spotlights new advanced manufacturing systems and SMOOTH TECHNOLOGY

Mazak hosted a record number of visitors through its booth during the six days of IMTS 2016, held at Chicago’s McCormick Place from September 12-17.

The company demonstrated over 20 highly advanced manufacturing cells and systems. Among these were its next-generation HYBRID Multi-Tasking technology that included a machine with both additive and subtractive capabilities as well as a machine that featured cryogenics to enhance milling performance and increase productivity. Visitors to the Mazak booth also experienced the company’s SMOOTH TECHNOLOGY that encompasses such advanced systems and cells as necessary for manufacturers to continuously improve, truly maximize efficiency and optimize their processes.

Mazak’s SMOOTH TECHNOLOGY platform – the foundation of Mazak’s iSMART Factory Concept – is revolutionizing today’s part manufacturing processes through smart machines, big data, sophisticated analytics and the Industrial Internet of Things (IIoT). As part of the platform, Mazak demonstrated the user-friendly programming capabilities and processing speed of its MAZATROL SmoothX and MAZATROL SmoothG CNC as well as its new MAZATROL SmoothC control at IMTS. These controls have transformed the way Mazak equipment performs, especially in terms of 5-axis and complex contouring operations.

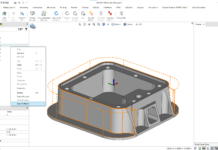

In today’s smart factories, Multi-Tasking and 5-axis machine tools with enhanced single-setup, DONE IN ONE® part-processing capabilities are crucial. And Mazak’s HYBRID Multi-Tasking technology, such as its new VC-500 AM HYBRID Multi-Tasking machine, are taking the concept to even higher levels of sophistication and output – building part features to near net shape up to ten times faster than other comparable systems.

The VC-500 AM – designed and manufactured in the Florence, Kentucky Mazak iSMART Factory – combines full 5-axis capability and additive technology to streamline product design, reduce time to market and cut R&D costs. In addition to this new compact, cost-effective machine, Mazak debuted new software and accessories that give it and other such Multi-Tasking machines even more functionality and multiple-process power.

At IMTS, Mazak also unveiled its new VARIAXIS i-800T Multi-Tasking Machine – developed through collaborative efforts – specifically to enhance milling operations and significantly boost productivity, especially for those manufacturers in the aerospace industry. With full 5-axis milling and turning capabilities along with integrated liquid nitrogen cryogenics technology, the machine not only delivers high processing efficiency for complex aerospace components, but also prevents the detrimental white layers typically generated when machining those parts from tough materials such as titanium, nickel, Invar and other exotics.

Mazak demonstrated the VARIAXIS i-800T cutting an aerospace jet-engine blisk. The machine featured an 80-tool magazine for continuous uninterrupted productivity and a 10,000-rpm, CAT-50 spindle for milling speed and power. The machine’s trunnion-style tilting table and multi-tasking capability allow users to reduce the inaccuracies that occur when moving parts across multiple workstations, eliminate work-in-process inventory and increase overall throughput.

Through collaborative efforts, Mazak has also advanced its Multi-Tasking machines with the addition of precision honing operations and closed-loop gear machining capabilities. All of which continue to further the company’s DONE IN ONE manufacturing solutions.

At IMTS, Mazak showcased various types and levels of automation. These included gantry systems, robotics and the company’s PALLETECH automated cell as well as new vertical pallet pools – all of which provide the flexibility to adapt to different types of machine tools as well as changing part processing requirements.

For those manufacturers needing a single-machine automation solution, Mazak featured its new Multi Pallet Pool (MPP) system that is compact and expandable and requires no special tables. The company also demonstrated its Smooth PMC software for easy, efficient and complete automated cell control.

Mazak’s enhanced Gantry Robot (GR) 50 with a special A/B-axis design also drew a lot of attention at the show. The system uses a B1 and B2 side-by-side axis configuration that basically doubles the system’s traverse speed for faster cycle times and increased productivity.

About Mazak Corporation

Mazak Corporation is a leader in the design and manufacture of productive machine tool solutions. Committed to being a partner to customers with innovative technology, its world-class facility in Florence, Kentucky, produces over 100 models of turning centers, Multi-Tasking machines and vertical machining centers, including 5- axis models. Continuously investing in manufacturing technology allows the Kentucky Mazak iSMART Factory to be the most advanced and efficient in the industry, providing high-quality and reliable products through its “Production-On-Demand” practice. Mazak maintains eight Technology Centers across North America to provide local hands-on applications, service and sales support to customers.

For more information on Mazak’s products and solutions, visit www.mazakusa.com or follow us on Twitter and Facebook.