Welcome to the Digital Age: A Success Story in 3D

The world is becoming more and more digital. This evolution has even made its way to traditional industries such as foundries. In order to facilitate the transition from traditional manufacturing processes to integrated industrial 3D printing, Bavarian technology company ExOne with its global headquarters in the United States has established successful partnerships with foundries and model workshops.

The integration of 3D printing technology for prototyping and production of sand cores and molds for castings, from low to large quantities, supports foundries in developing their business models.

By no longer having to rely on conventional model equipment, the 3D printing process considerably reduces production times and thus also the cost. ExOne places special emphasis on maintaining a good and close working relationship with its partners. Throughout the development and production process, the focus is on ensuring that customers will be able to implement new concepts in terms of design, prototypes and production parts precisely as required.

While the company offers its services to customers from a wide range of industries in its production service centers found around the world, the Gersthofen plant manufactures only 3D printing systems for sand molds or cores. Traditional industrial wgrade materials such as silica sand and ceramic are being used in pioneering ways.

The continuous development of products and processes is essential to ExOne’s active innovation strategy. We are constantly working to improve our products and processes. The development department is constantly testing new materials and processes to qualify them for eventual use in serial production. The top priority is always our customers and their products, because ExOne’s goal is to provide the best possible support to companies as they transition from traditional manufacturing processes to integrated industrial 3D printing.

ExOne’s business is built on working closely with our customers. As a world leader in the production of sand printing systems, ExOne has realized visionary ideas with its partners. From the initial idea to the final delivery of the products, the high-tech company guarantees its customers a smooth workflow.

Entire machines are manufactured exactly according to customer wishes, with every detail highly customized to meet their specific requirements. The high-quality production at ExOne ensures replicable quality in the production of 3D printing systems. Perfectly conceived and executed production and assembly processes ensure maximum precision and maximum availability of the machines in subsequent industrial use.

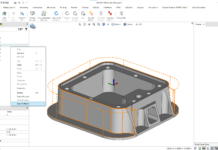

True to the last detail and precisely implemented sand molds and cores in highly complex geometries from high performance ExOne 3D printers sand molds! The forms also feature outstanding sharpness and mechanical strength. Even as the shapes become quite complicated with undercuts, the printing systems deliver first-class results. On top of that, the 3D printing can turn around the sand molds at speeds unimaginable just a few years ago. It can take several weeks to complete the modeling equipment in conventional form production. The 3D forms do not require time-consuming and expensive models and are instead fully automatic and driven purely by CAD data. Any changes or adjustments to account for casting methods can be implemented directly while ensuring less need for post-casting work on the finished product thanks to their high surface finish and exemplary dimensional stability.

The current range of machines from ExOne covers all applications from prototyping to mass production. S-Print, S-Max, and Exerial, ExOne’s flagship for industrial mass production offer dimensions and speeds that ensure industrial quality in the rapid production of complex sand molds and cores. Even in the harshest environments, ExOne’s machines deliver durability and dependability while being some of the fastest 3D printers on the market. Ease of use, high productivity, accuracy, and able to produce complex geometries for different casting applications make them the machines of choice for many operations.

In order to satisfy even the highest demands, every ExOne product is subjected to a 3D test process using optical measurement equipment before delivery. The quality management system leaves nothing to chance and the parts we supply are also subject to the same strict quality standards. Prescribed test steps are consistently applied to ensure compliance with strict tolerances at every stage of production.

When printing complex parts made of industrial grade materials, ExOne uses proven binder jetting technology. This is an additive production process where the activated sand is applied layer by layer on the building platform. Not unlike the ink in inkjet printers, the liquid binder is applied by the print head to the sand layer and binds to the material. The targeted application of the binder ultimately creates the 3D geometry. This technology allows the production of highly complex shapes and there are no limits to the design. Further advantages compared to other additive manufacturing processes are obvious: binder jetting does not require a fixed build plate, since the parts are supported by the loose powder in the job box. Several different parts can be produced in a single print bed. And the printing time is significantly shorter than with other methods. The ability to manufacture complex components thus saves additional costs.

About ExOne

The ExOne Company was founded in 2005 as a spin-off of Extrude Hone Corporation, a global supplier and developer of precision nontraditional machining processes and automated systems for more than 50 years. Three-dimensional printing emerged as the core technology for The ExOne Company, which currently supplies services, systems and solutions for manufacturing in the digital age, including three-dimensional printing in industrial grade materials such as sand and metals.

Please visit www.exone.com for more information.