Students of the engineering physics program at the University of British Columbia (UBC) in Vancouver, Canada are highly focused on advancing science through new, high-tech inventions. Therefore, the university relies on OMAX waterjet technology to fabricate the precision parts that bring student creations to life.

Examples of what UBC students can invent using advanced OMAX waterjet machining, including a harmonograph system for drawing intricate 2D patterns, a new spoke-free suspension system for a bicycle and an unmanned aerial vehicle, will be on display during the university’s 2012 Engineering Physics Project Fair on March 6.

Furthermore, because OMAX waterjets are key learning tools within all UBC engineering departments, from physics to chembiological, the university is having Dr. John H. Olsen, OMAX co-founder and vice president of operations, speak to students about his vast knowledge of the waterjet industry during the project fair.

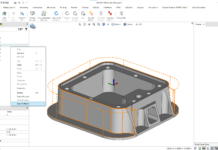

According to Dr. Jon Nakane, director for the UBC Engineering Physics Project Lab, he believes OMAX makes high quality machines that offer amazing speed and simplicity, which is critical for an academic environment. He said the OMAX 2652 JetMachining® Center in his lab successfully cuts through almost any type of material, including sheet steel, aluminum, Lexan and other plastics, circuit boards, rubber sheets for custom gaskets and plywood for press-fit shapes. He also noted students have machined items as small as single millimeter-thicknesses to as large as barely fitting on the machine’s bed.

“After years of fabricating items using traditional mills and lathes, and submitting parts to our professional in-house machine shop for CNC fabrication, my department’s OMAX machine lets students fabricate parts and get working solutions faster and easier than before,” said Nakane. “My students love the fact that they can get their parts designed and ‘working’ in CAD, then see how closely they can get to a real-world object using the waterjet cutter.”

Unlike conventional mill and lathe machining processes, the OMAX 2652 provides the quick turnaround of accurate parts without the hassle of tool changes or complex fixturing. Furthermore, the 2652 produces smooth surface finishes, eliminating the need for secondary machining. Plus, students get to enjoy clean, safe machining operations that are free of noxious gases, liquids and oils.

In addition to the OMAX 2652 in the Engineering Physics Lab, the UBC also owns a second 2652 as well as three OMAX 2626 JetMachining Centers and a MAXIEM® 1515 JetCutting Center.

“We appreciate the high level of service and support we receive on all of our waterjet machines from OMAX,” concluded Nakane. “Parts arrive quickly, the people are helpful and the level of documentation for the care and regular maintenance of the machines is impressive.”

About OMAX

Headquartered in Kent, Washington, OMAX ® Corporation is the world leader in abrasivejet machining. Each OMAX JetMachining® system and MAXIEM® JetCutting Center is powered by the company’s innovative control software, bringing affordable abrasivejet technology to an expanding and diverse group of industries.

OMAX Corporation

21409 72nd Ave South

Kent, WA 98032 USA

(800) 838-0343

P: (253) 872-2300

F: (253) 872-6190 (corporate)