The skilled labor shortage is real. But so is the opportunity to reinvent how work gets done. Path’s intelligent welding systems are bringing the future back into focus — and back onto the factory floor.

[CHICAGO, IL – September 9–11th, 2025 | Booth #B17033] Remember when we thought robots would do our homework? At Path Robotics, we’re not doing your algebra, but we are building robotic welders that can think, plan, and adapt, and they’re changing the future of manufacturing.

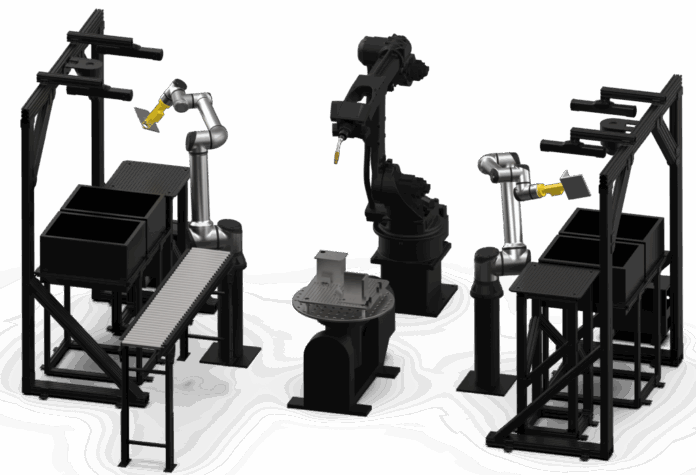

As America faces a shortfall of over 320,000 welders by 2029, the question isn’t whether we need help, it’s how fast we can deploy it. At FABTECH 2025, Path will showcase its AI-powered welding platform: a modular, no-code, vision-driven system built for one purpose — to keep America building, even when the labor isn’t there.

This Is Not Your Grandfather’s Robot

- Path’s system doesn’t just repeat. It sees. It learns. It adapts.Vision System:

- Captures mm-level variation across real-world parts

- Weld World Model: Simulates and adjusts weld plans on the fly

- JobBuilder: Lets engineers drag, drop, and deploy without programming

- Modular Fixturing: Keeps high-mix workflows moving without delay

All together, it delivers:

- Arc-on time: 70–90%

- First-pass yield: 95–100%

- Deployment: <100 days

- Labor equivalent: 1 system = up to 12 welders

- Cost reduction: Up to 45% per inch

Built in Columbus. Designed for the Country.

Path’s robots aren’t coming soon. They’re here. Already in shipyards, steel plants, and fabrication floors. They’re built in Columbus, Ohio, and they’re making an impact.