ABB invests in strategic partnership with US start-up Molg to transform drive design and accelerate its contribution to the circular economy

- Investment by ABB Drive Products to develop next generation products for circularity and resource-efficient future

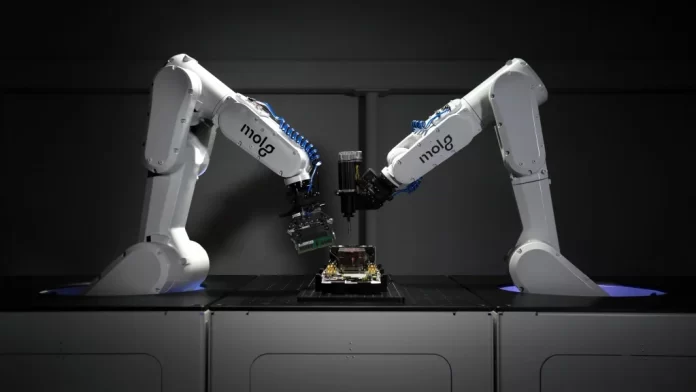

- Companies will develop design architecture for drive manufacturing by optimizing testing and assembly processes in Molg’s robotic Microfactories

- Collaboration started in 2024, with ABB Robotics participation in Molg’s seed round of funding

ABB Motion’s Drive Products division has invested, through ABB Motion Ventures, in Virginia-based circular manufacturing company Molg to optimize manufacturing design and reusability of ABB drives. The collaboration will leverage Molg’s design expertise and US-based robotic Microfactories to streamline the assembly and testing processes within ABB’s manufacturing operations, while simultaneously increasing drives’ circularity and resource efficiency.

ABB and Molg’s relationship began in 2023 when the company was recognized as a winner of the ABB Accelerating Circularity Startup Challenge. ABB Drive Products and Molg have subsequently delivered a successful proof of concept in drives assembly in robotics-based Molg Microfactories and this fresh investment will enable the next phase of their partnership.

A central aspect of ABB Drive Products’ choice to invest in Molg is the firm’s circularity credentials. ABB is committed to achieving a full life cycle circular approach for 80 percent of its products by 2030 and Molg’s robotic Microfactories will help to improve the efficiency of manufacturing configured-to-order drives by streamlining the assembly and testing processes with automation. The investment strengthens ABB’s position as a key enabler of circular economy by re-using, re-purposing, and recycling components. ABB Robotics & Automation Ventures participated in Molg’s seed round of funding in October 2024 to help scale the start-up’s production capacity and tackle e-waste with robotics and design.

This strategic partnership follows ABB’s recent $100 million campus project in New Berlin, Wisconsin, and further enables its ‘local for local’ strategy – using locally-sourced materials for in-country manufacturing to service local customers. This is also a vital part of ABB’s circularity-based approach, not only minimizing waste and manufacturing-related carbon emissions, but providing crucial in-market support for companies across the supply chain.

“Our investment in Molg means we are part of an innovation ecosystem which develops new solutions for product circularity,” said Tuomo Hoysniemi, ABB Drive Products Division President. “This investment to develop our drives portfolio through recycling and reusing of components is aligned with our aims to increase circularity within our portfolio. What’s more, Molg’s Microfactories are especially suited to the ABB Drive Products’ customizable product range and will give us and increased ability to meet unique customer and market future requirements, while at the same time preserving valuable resources.”

“Winning ABB’s Accelerating Circularity Startup Challenge was great recognition for us, and we are even more excited to continue our collaboration with ABB Drive Products within circularity and automation,” said Rob Lawson-Shanks, CEO & Co-Founder of Molg. “We are thrilled to work with ABB Drive Products to design more circular products and create circular manufacturing processes for electronics to enhance supply chain resilience and ensure valuable materials are kept in circulation.”

The financial details of the investment have not been disclosed.

About ABB

ABB is a global technology leader in electrification and automation, enabling a more sustainable and resource-efficient future. By connecting its engineering and digitalization expertise, ABB helps industries run at high performance, while becoming more efficient, productive and sustainable so they outperform. At ABB, we call this ‘Engineered to Outrun’. The company has over 140 years of history and around 110,000 employees worldwide. ABB’s shares are listed on the SIX Swiss Exchange (ABBN) and Nasdaq Stockholm (ABB). www.abb.com

ABB Motion Ventures is the venture capital unit of ABB Motion. ABB through its business-led venture capital investment framework, ABB Ventures, looks for breakthrough technology companies aligned with ABB’s goal to write the future of industrial electrification and automation. Since its formation in 2009, ABB Ventures has deployed around $500 million into startups spanning a range of sectors including robotics, industrial IoT, AI/machine learning, energy transition, cybersecurity, electric mobility, smart buildings, and distributed energy. For more information, visit www.abb.com/ventures

About Molg

Molg tackles the growing e-waste problem by making manufacturing circular. The company’s robotic microfactory can autonomously disassemble complex electronic products like laptops and servers, helping keep valuable components and materials within supply chains and out of landfills. Molg partners with leading electronics manufacturers to design the next generation of products with reuse in mind, ensuring that one product’s end is another’s beginning. To learn more, visit molg.ai.