I understand there are different types of cobots. What are the general categories?

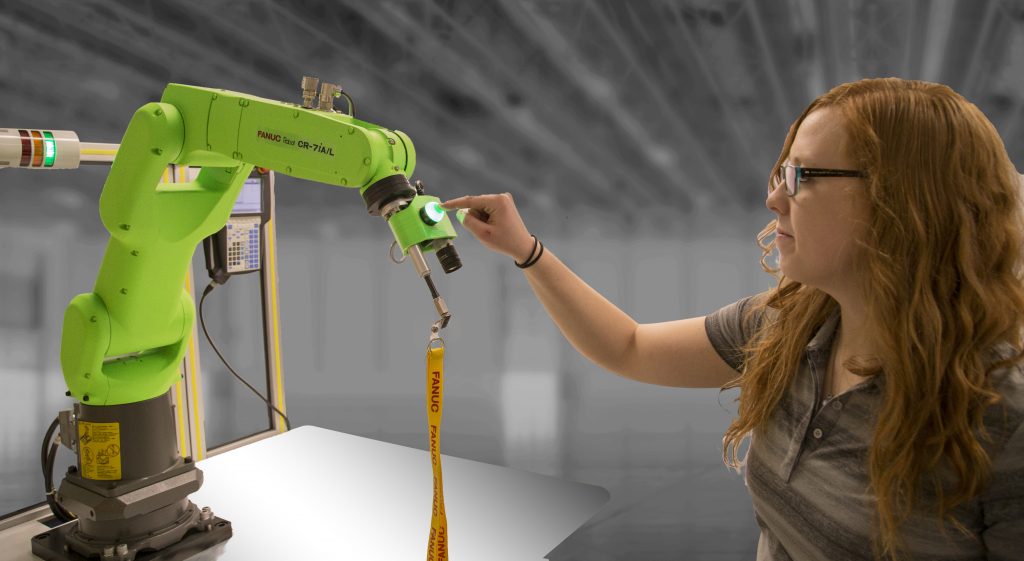

There are four types of collaborative robot operation, beginning with Power and Force Limiting cobots, which are probably what most people are thinking of when they hear the term collaborative robots. They are designed specifically to be able to sense contact with human workers and cease operation, eliminating the need for safety barriers. They are best suited for smaller applications. For the other three types of collaborative operation, any industrial robot can be integrated with safety devices to be able to become “collaborative” Safety Rated Monitored Stop cobots, which detect when a person has entered a designated area and stops operating until the person leaves that shared workspace, which eliminates the need to have to restart the robot with the push of a button. Once the person leaves, the robot can continue automatically with its task. These are generally used when there isn’t as much interaction between people and the cobot. Speed and Separation cobots, also sometimes referred to as “fenceless,” work well when there is not much interaction with a person, but a person needs easy access to the robot. Safety laser area scanners are commonly used to set up zones near the robot’s workspace so that when a person starts to approach the robot, its movement is slowed down, and it stops altogether once that person gets within reach of the robot’s workspace. As soon as the operator moves out of the robot’s workspace, the robot can resume what it was doing automatically. The final category is known as Hand Guiding cobots, which is where a safety rated device is attached to the end of the robot arm and allows someone to manually guide or move the robot around. This type is often used to help program new paths and positions quickly and easily in just that way — by hand. This type is ideal for mobile applications, moving the cobot between stations and training it to accomplish different tasks, and where the robot needs to frequently be reprogrammed for a new job.

What were some of the biggest challenges that had to be overcome when cobots as we now know them were first introduced into the industrial environment?

What were some of the biggest challenges that had to be overcome when cobots as we now know them were first introduced into the industrial environment?

As can be expected, we needed to help people overcome the notion that cobots were going to replace their jobs, when they were actually there to function as an assistant in tasks that a person either wouldn’t want to do, like picking parts all day, or would find physically difficult, like lifting heavy objects. A cobot could lift a large car door during assembly, for instance, and hold it in place while a worker made the delicate electrical connections that a cobot couldn’t accomplish. Just from an ergonomic standpoint alone, cobots are a real asset to anyone working long hours on the production floor. Another challenge involved risk assessment, during which the determination is made as to whether a cobot would be suitable for a particular workspace or application. While it’s a definite space-saving benefit of a cobot to be able to eliminate the safety enclosure, you have to remember there are many other moving parts within that work area — there’s a lot more going on in there than just the cobot’s activities. So there are a lot of variables to take into consideration. We had to rethink things like exposure to pneumatic mechanical grippers, and how to keep people safe working near them, so there were a whole host of issues to consider. Nothing can ever be taken for granted in the manufacturing environment.

At the same time, what are the primary benefits that have been realized over the years?

At the same time, what are the primary benefits that have been realized over the years?

Again, the space savings gained by eliminating the safety enclosure really streamlines the workspace, and the flexibility you gain by being able to move a cobot from station to station was a huge asset that people immediately recognized and appreciated. In fact, I think one of the capabilities we hadn’t quite envisioned at the beginning of all this that has turned out to be a huge value-add is how well suited cobots are for high-mix/low volume applications. If you take a look at our new CRX Series, you’ll notice that we’ve paid a lot of attention to things like ease of installation as well as the simplification of teaching it to perform new tasks and functions. That allows users to quickly move from one job or one part to another without having to invest too much time or effort into setting up for whatever needs to be done next. Plus the CRX cobots are lightweight and easy to handle, making them ideal for mobile applications. And another thing we’ve done is designed them to support a new tablet teach pendant as the HMI between the operator and the cobot, which is a much more familiar means of digital communication for most people. And as we see advances in AI, making cobots and other robotic and automatic systems more intuitive, the interface between operator and machine is becoming more fluid and productive, really underscoring the collaborative nature of this technology.