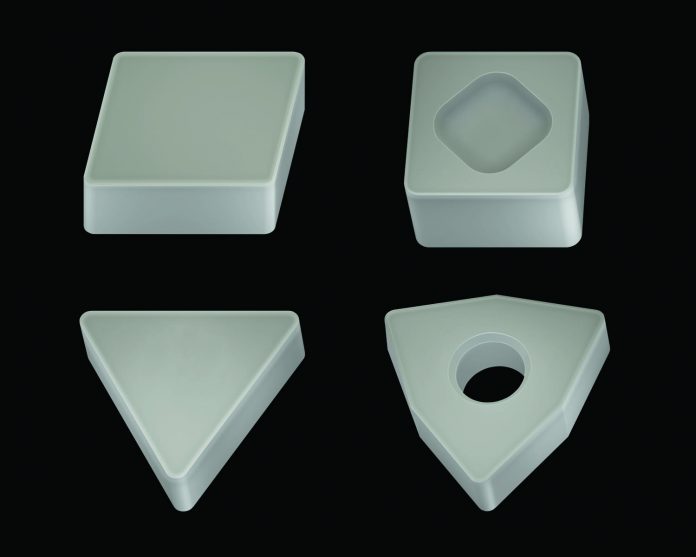

The new WCK10 ceramic cutting grade from Walter is optimized for roughing gray cast iron at high cutting speeds, with either continuous or interrupted cutting. The inserts deliver improved productivity, process reliability and longer tool life due to their new Si3N4 wear-resistant ceramic cutting material.

Because the Si3N4 ceramic cutting material permits higher cutting speeds and higher cutting volumes than traditional solid carbide, production time and costs are reduced. In addition, the new WCK10 inserts feature a negative chamfer for longer tool life, stable dimple clamping, and the ability to handle both wet and dry machining. Users also benefit from their attractive price-performance ratio.

About Walter

Walter, a global leader in the metalworking industry with over 90 years of experience in precision cutting tools for milling, drilling, turning, boring and specialized tools, helps customers improve process reliability and increase productivity. With Regional Headquarters in Waukesha, WI, Walter markets its competence brands Walter Valenite, Walter Titex, Walter