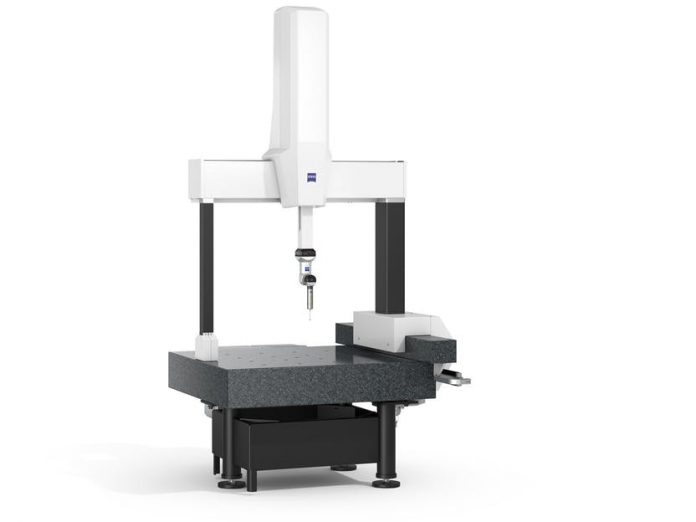

Designed for general measurement, the SPECTRUM can be configured to meet your specific needs. With the Carl Zeiss RDS-C5 articulating probe holder and our XDT multi-point sensor or Renishaw TP20 touch-trigger, this CMM can measure angled features in difficult to reach locations. The articulating probe holder offers +/- 180 degrees of bi-directional rotation and permits indexing steps of 5 degrees reaching 5,184 angular positions for either sensor. SPECTRUM can also be configured with the XDT directly for general prismatic applications.

SPECTRUM models offer x, y, z measuring ranges from 700 x 700 x 600 mm to 700 x 1000 x 600 mm. Hard-coat aluminum guideway elements offer a variety of benefits including corrosion resistance, hardness and wear resistance, electrical resistance, temperature resistance and a low friction coefficient. The machine’s accuracy of up to MPEe 2.1 + L/250 is guaranteed over a temperature range from 18 to 22°C (64-71°F).

This system is equipped with a C99L Controller reducing the need for additional floor space. It provides smooth, accurate, high-speed 3-axis CNC movement for all measuring tasks and the dual-joystick panel makes motorized control easy. The ZEISS wrap-around air bearings in all guideways provide rigidity and stability at maximum speeds and accelerations.

SPECTRUM is available with user-friendly CALYPSO metrology software. CALYPSO is a revolutionary CAD-based software with Visual Metrology. There is no time-consuming, structural programming or difficult code and text editing.

Janelle Gregerson | Carl Zeiss, Industrial Metrology

janelle.gregerson@zeiss.com