Rockford Systems LLC, a leader in machine safeguarding solutions, introduces PROTECTOR™ Series Shields for safeguarding cutting and turning machines, such as drills, mills, lathes, grinders and more. This highly innovative and patent-pending product line improves the safety and productivity of operators working with dangerous machinery.

“For nearly 50 years, Rockford Systems has been a leader in machine safeguarding due to our relentless commitment to quality, meeting the needs of our customers, and developing innovative solutions that solve their safety problems,” said Matt Brenner, Vice President of Machine Safeguarding Services for Rockford Systems, LLC. “We have learned that customers are not happy with machine safety shields available on the market today. Operators complain that safeguarding shields limit their visibility and impede their work, supervisors report that shields can be bypassed or disabled making machines unsafe to operate, and EHS leaders need to demonstrate a positive Return on Investment (ROI) by maximizing safety while minimizing expenses. PROTECTOR Series Shields solve all of those problems.”

SOLVING COMMON PROBLEMS

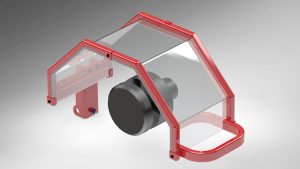

PROTECTOR Series Shields are constructed of 14-gauge powder-coated steel and thick 3/16″ shock-proof, scratch-resistant polycarbonate, creating an extremely tough, rigid and durable safety shield that protects operators from flying debris, lubricants, coolants and swarf. They incorporate cool, bright LED lighting into the shield frame to yield superior visibility of the work area, thereby improving the safety and satisfaction of the operator. Additionally, PROTECTOR Series Shields are offered in both non-interlocked and interlocked versions; the interlock disengages power and prevents a machine start-up when the shield is not in the correct work position, thereby solving the bypassing problem. The safety-rated interlock switch is enclosed in a NEMA 4 tamper-resistant housing with an optional safety monitoring relay, which monitors the interlock switch for failure or damage. Further, PROTECTOR shields are modular in design and easily configurable to tailor a custom fit for any machine application, thereby optimizing employee safety and generating a positive ROI.

MODULAR DESIGN

PROTECTOR Series Shields are modular in design so that shield shape, size, mount, arm, offset, lighting, interlocking and safety monitoring can be configured to provide the best solution for even the toughest machine guarding challenge. Available with various mounting options, these high-quality shields allow for reversal to address opposite-hand mounting scenarios when necessary. All shields are vertically and horizontally adjustable to clear varying work setups and table heights.

PROTECTOR Series Shields are modular in design so that shield shape, size, mount, arm, offset, lighting, interlocking and safety monitoring can be configured to provide the best solution for even the toughest machine guarding challenge. Available with various mounting options, these high-quality shields allow for reversal to address opposite-hand mounting scenarios when necessary. All shields are vertically and horizontally adjustable to clear varying work setups and table heights.

WORKSPACE SAFETY LIGHTING

PROTECTOR Series Shields can include color-changing LED lighting nested into the frame of the shield to illuminate the work area during machine operation. The LED light strip is integrated into the shield frame and each strip packs 262 Lumens of light per linear foot. For example, the PROTECTOR 28″ octagonal or circular shield provides 2180 Lumens, compared to a typical clip-on work lamp that provides only 800 Lumens. Operators will appreciate the non-reflective, true-color rendering white light illuminating their work area. When the shield is moved out of the safe work position, white LEDs switch off and red LEDs switch on, thereby providing visual indication that the shield is in the open position. All LED lighting has been manufactured to exacting IEC IP65 outdoor/wet location standards to withstand coolant and lubricant splashes.

SAFETY INTERLOCKS & MONITORING

PROTECTOR Series Shields can be upgraded with a safety interlock switch or switches, dependent upon application. Interlocking shields exceed OSHA regulations and ANSI standards, and are considered a best safety practice.

Shield interlocks shut off or disengage power and prevent machine start-up when guard is not closed, thereby increasing operator safety and preventing bypassing. All safety interlock switches are mounted in a tamper-resistant NEMA 4 housing, comply with the IEC/EN 60947 safety standard and carry IEC IP66/67 device ratings. Additional motor starter or anti-restart devices may be required when incorporating interlocking devices into the PROTECTOR Series Shields in order to ensure safe and compliant operation.

MADE IN THE USA

In recent months, it has become clear that complex international supply chains are not resilient to the immediate sourcing needs of organizations. PROTECTOR Series Shields are manufactured by Rockford Systems LLC in Rockford, Illinois, USA and available for immediate ordering.

More information can be found here.

ABOUT ROCKFORD SYSTEMS LLC

Headquartered in Rockford, Illinois, Rockford Systems LLC delivers industrial plant safety solutions for organizations using metalworking, automation, material handling or thermal processing in their operations. Since 1971, Rockford Systems has specialized in the design and installation of over 25,000 safeguarding solutions for industrial fabrication equipment and manufacturing systems that exceed applicable safety regulations and standards.

Rockford Systems offers trusted industrial turnkey safeguarding solutions including scalable assessments, audits and inspections, training and education, consulting and policy development, and over 10,000 safeguarding products. Rockford Systems also provides turnkey combustion safety solutions including assessments and inspections, as well as standardized and customized valve safety trains. These extensive risk reduction solutions enable organizations to dramatically improve compliance and worker safety while maintaining productivity.