Additive Innovation (AI), a company specializing in additive manufacturing, is now distributing the innovative 3D Printer with LCD Screens, printers and materials of the renowned English manufacturer Photocentric in Germany, Austria, and Switzerland.

Innovative DLP 3D Printer with LCD Screen

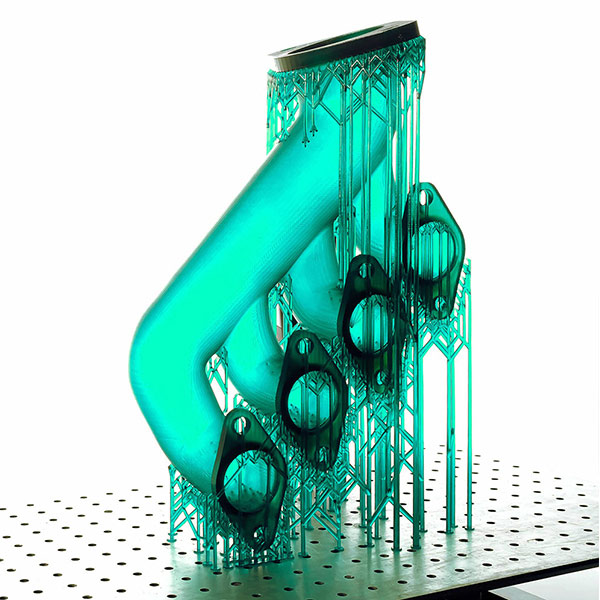

The LC Magna 3D printer is the largest SLA printer with LCD screen currently available, according to the manufacturer. The innovative device has a 4K Ultra HD screen with 50 micron accuracy and enables a print speed of 13.3 millimeters (mm) per hour. In addition, to a build volume of 510mm x 280mm x 350mm, the printer offers high printing accuracy, allowing component designs with very fine surface textures such as leather or technical patterns to be printed in high resolution.

Flexible Material

Photocentric’s daylight and UV resins enable economical production at material costs starting at around 35 euros per kilo. The material can be used for various applications in prototyping, mechanical engineering or in the dental and automotive industries. The materials are used in LCD, SLA and DLP 3D printers, for example, and are also compatible with 3D printers from other manufacturers such as Asiga, Envisiontec, Flashforge, Formlabs, Peopoly and Sprint Ray, according to Photocentric.

Integrated Software Solution

In cooperation with CoreTechnologie, Photocentric and Additive Innovation, integrated software for LC Magna machines has been developed. With the so-called Photocentric Additive Tool, 3D models can be read in from common CAD formats and prepared as an exact, intelligent B-Rep model. Special tools for the generation of support geometry, textures, grid structures as well as modeling functions such as offset surfaces, hollowing with or without internal grid structures, 3D cutting as well as scaling and mirroring are now available as a fully integrated and easy-to-use software solution for Photocentric machines.

Background Information

As a spin-off of the globally successful software manufacturer CoreTechnologie and sales partner of Photocentric, the company Additive Innovation GmbH from Mömbris near Aschaffenburg, which was founded in January 2018, supports companies in efficiently realizing the advantages resulting from additive manufacturing. Additive Innovation’s mission is to provide 3D printing services and optimize additive manufacturing processes. The focus is on quality and the use of state-of-the-art hardware and software tools. Thus, the innovation driver pursues a holistic approach to service, system integration as well as the evaluation and implementation of 3D printing processes in companies. The Additive Innovation team has direct access to CoreTechnologie’s software tools, which are always at the cutting edge, as well as to the cutting-edge know-how of its technology partner Photocentric. This allows Additive Innovation’s innovation team to respond immediately to new requirements with intelligent functions and enable a seamless transition from design and 3D model to 3D print.