When it comes to fastening lightweight metals, as well as a fastening needing to be reliable, the focus is on optimising installation space and on performance and cost optimisation. Against this background a crucial point is the load-bearing capacity of the fastening.

It is precisely for such applications that Arnold Umformtechnik GmbH & Co. KG has developed Powertite. – a round thread-tapping screw with a trilobular tapping zone. This means that at the deformation point the screw has a slightly triangular cross-section (rounded edges) to reduce the tapping torque. The length of the tapping zone at 3 x p (p=thread pitch) is optimised for the installation space, allowing the forming energy created by the thread-tapping process to be distributed over several thread turns and giving optimal setting and centring of the screw. The round load-bearing cross-section has a defined overlap, the external diameter of the screw is always greater than the nominal diameter. This ensures a greater overlap of the screw’s thread edges and tapped nut thread. The combination of the trilobular shape in the tapping zone and the round cross-section in the load-bearing section achieves a significant improvement in thread-tapping screw fastenings. This is because firstly, the tapping torques are low and secondly, because the load capacity of the tapped nut thread is considerably greater.

Major savings potential

There are many examples of applications for the thread-tapping Powertite screw. For example, applications in which maximum preload forces need to be achieved with plastically stressed assembly. And Powertite is also suitable for components into which only very short penetration depths can be made and high hole tolerances are necessary. Furthermore, in many cases it is possible to reduce weight by reducing the length of the screw and optimising the weight of the head.

Two specific examples illustrate how even a tiny screw can be a climate protector within a specific product. Since June 2022, a Powertite M7x40 has been implemented in a load transmission unit, currently still used in combination with combustion engines. With 13 screws in each transmission unit and a requirement for some 6 million screws per annum, by using Powertite in this unit alone there is a saving of around 19,400 kg in weight and a reduction in CO2 by 33.1 tonnes each year.

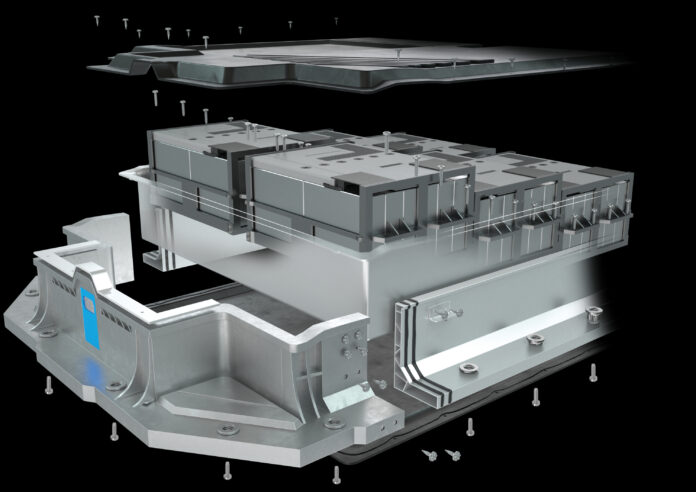

The saving is even greater in an e-motor transmission unit where 33 screws are used for each unit. Of the 50,000 vehicles planned each year, it is forecast that 30,000 will each be fitted with two e-motor transmission units. Projected over all 50,000 vehicles and the 80,000 transmissions needed the total number of screws required is around 2.64 million a year. Simply by using Powertite it is possible to achieve a weight-saving of some 8,519 kg and a carbon reduction of 33.1 tonnes each year in the manufacture of these vehicles.

Enhanced thread-tapping technology

According to Arnold Umformtechnik, Powertite, with its perfect geometric fit, increases load-bearing capacity in the tapped nut thread by over 20 percent compared to screws with trilobular load-bearing cross-section. That creates a series of technical and commercial benefits: standards-compliant tapping torques, plastically stressed assembly even into conical cast core holes in Al-Gd, a preload force similar to metric fastenings, and the possibility of larger core hole tolerances to optimise lightweight metals casting. As well, assembly reliability is very good, and it can also be used in steel, aluminium and other lightweight metals. Furthermore, it is possible to make the screw fastening repeatedly and they can be replaced by metric screws if needed for servicing.

The main focus of Powertite applications lies on electro-mobility. This is especially true for lightweight metals, but it also applies when combined with cast components.

The product, which has already been patented, was launched on the market in October.

As always, potential customers can access the complex product knowledge held by the Forchtenberg-based (south-west Germany) fastener manufacturer, as well as a full understanding of the product’s performance in the various applications and sectors. This is supplemented by the relevant calculation tools and wide-ranging manufacturing expertise. Together with its development partners in the vehicle manufacturing sector Arnold Umformtechnik has developed a completely new manufacturing process especially for Powertite.