The new Cermet WEP10 indexable turning inserts from Walter deliver long tool life and high productivity. Their fine-grain titanium carbide substrate with Ni/Co binder produces a stable cutting edge. Combined with an extremely hard TiCN outer layer, this grade provides multiple advantages during finishing operations when compared to carbide inserts.

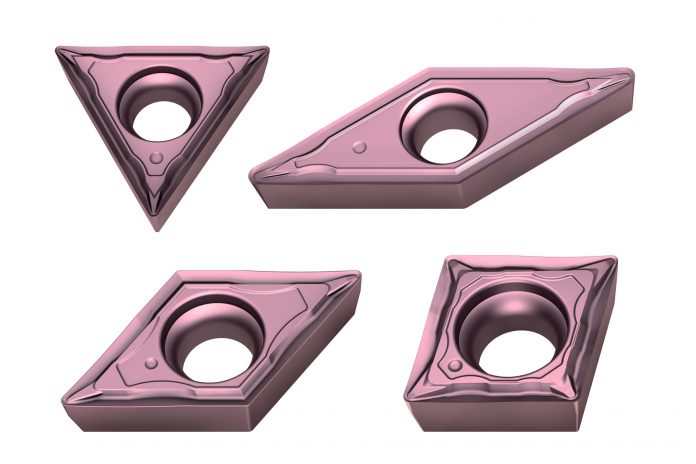

These advantages include increased tool life due to its high wear resistance, no necessity for readjustments, and maximum dimensional accuracy. In addition, Cermet WEP10’s FP4 soft-cutting insert geometry is suitable for finishing a range of different materials. The FP4 geometry, with its unique edge preparation is capable of yielding mirror finish surfaces at high or low cutting speeds. A variety of insert shapes are available.

Application areas for the new Walter Cermet WEP10 include finishing operations with continuous or slightly interrupted cut in steels, stainless steels, and cast-iron workpieces. Targeted industries can be general metalworking, mechanical engineering, energy, and the automotive industries.

About Walter

Walter, a global leader in the metalworking industry with over 90 years of experience in precision cutting tools for milling, drilling, turning, boring and specialized tools, helps customers improve process reliability and increase productivity. With Regional Headquarters in Waukesha, WI, Walter markets its competence brands Walter Valenite, Walter Titex, Walter Prototyp and Walter Multiply through a strong network of distributors and field engineers across subsidiaries in the USA, Canada, Mexico, Brazil and Argentina.

Walter USA, LLC

N22 W23855 Ridgeview Pkwy West

Waukesha, WI 53188

P: (800) 945-5554

Kurt Ludeking | Director of Marketing

kurt.ludeking@walter-tools.com