30% thicker coating and new heat treat process to increase fatigue life.

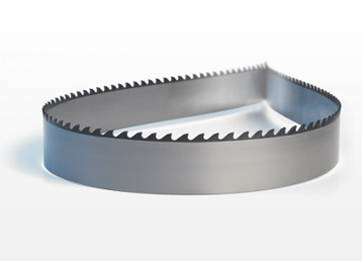

LENOX®, a leading manufacturer of premium power tool accessories, hand tools and band saw blades, introduces an improved LENOX ARMOR CT BLACK®. Providing a faster cut and even higher productivity, the ARMOR coating combines Aluminum, Titanium and Nitrogen (AITiN) to form a tough coating that protects each tooth from heat and wear with an armor-like barrier.

LENOX®, a leading manufacturer of premium power tool accessories, hand tools and band saw blades, introduces an improved LENOX ARMOR CT BLACK®. Providing a faster cut and even higher productivity, the ARMOR coating combines Aluminum, Titanium and Nitrogen (AITiN) to form a tough coating that protects each tooth from heat and wear with an armor-like barrier.

“LENOX products are always at the forefront of innovation, technology and quality, and the new Armor CT Black is a great example of LENOX delivering on that promise” explains Matt Lacroix, director of marketing at LENOX. “LENOX is known for providing solutions. Armor CT Black allows our customers to cut at extreme rates, which drives increased productivity and efficiency in the cutting operation. Those benefits go straight to the bottom line.”

Other highlights of the improved LENOX ARMOR CT BLACK:

Other highlights of the improved LENOX ARMOR CT BLACK:

- Extends blade life by preventing heat built up. Improved, thicker coating now forces even more heat into the chips, instead of the blade or workpiece

- High performance backing steel with excellent fatigue life. Optimized heat treat and backing steel preparation minimizes premature band breaks

- Tailored to cut a wide range of metals. High quality, micro grained carbide tips

Applications include: carbon steels, mold steels, alloy steels, tool steels, bearing steels, stainless steels, structural steels and titanium alloys.

To learn more about LENOX please visit:

www.lenoxtools.com

LENOX recently announced the UpBlade Challenge at:

www.oneblade.com

About LENOX

LENOX began in 1915 with a 10-employee team and a passion for bringing customers hacksaw blades that cut faster and lasted longer. Now, more than 95 years later, our passion hasn’t changed—but our team has grown to more than 900 people who manufacture and market the LENOX products in more than 70 countries. Our ISO 9001-certified facility in East Longmeadow, Mass., boasts a 500,000 square ft., 11-acre space for designing, testing and manufacturing power tool accessories, hand tools, band saw blades and accessories.