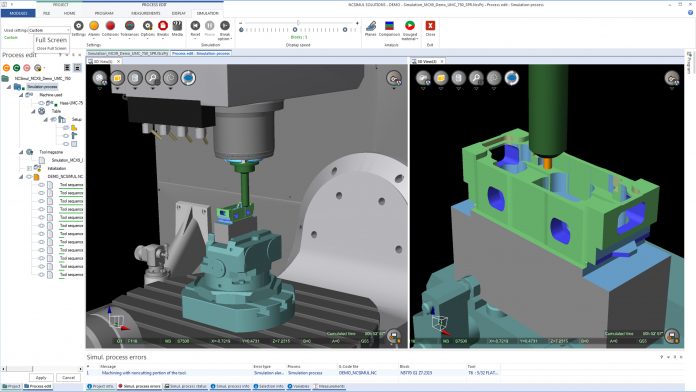

SPRING Technologies, software provider for enhancing the efficiency of CNC machines, is pleased to announce that the release of 2018 NCSIMUL is available now and will officially launch at IMTS 2018 in Chicago during the week of September 10 – 15. The company’s booth is E-133267. “Everywhere in the world, Industry 4.0 and the digital channel are, more than ever, important issues to manufacturers,” said Silvère Proisy, North American Operations Manager. “The new NCSIMUL release, together with its modules, place digitalization at the core of the workshop, and especially at the service of people, to improve the competitiveness and reliability of manufacturing.”

Highlights of the latest release include improving forecasts, reducing operating cycles, automating and making production reliable – whatever the numerical control machine tool (CNC) – and allowing the company to capitalize its knowledge and expertise. All of these attributes result as valuable assets for manufacturing companies. Furthermore, a numerical chain that links openly and automatically from the engineering department to the shop floor, is a real need and provides a genuine decision-making tool for programmers and operators working at the machines.

NCSIMUL 2018: New Features

The following modules have been improved, according to the demands of the customers and the market needs: Collision-free NCSIMUL MACHINE; CNC part transfer – 4CAM; Operation cycle reduction – OPTITOOL; Automatic Verification – AUTOMATION; Program transfer – DNC ; Machine status monitoring – MONITOR ; Technical Sheets – PUBLISHER; immersive, collaborative and mobile 3D – PLAYER.

The main innovations of the 2018 release are:

- NCSIMUL OPTITOOL

- This module can be added to SPRING’s two key products: NCSIMUL MACHINE and NCSIMUL 4CAM.

- In NCSIMUL MACHINE: Provides existing G-code optimization, and the resulting rewritten program offers efficiency gains anywhere between 5 and 25%.

Optimization of toolpaths (imported, converted, or programmed) with NCSIMUL 4CAM. - Turning, in addition to milling, is newly accounted for, giving the user the opportunity to better understand (their/the) tool wear rate.

- User experience is improved with, and automation of before/after comparisons, allows for faster analysis of the results at the machine and helps to make the right decision about the optimal machining program.

- NCSIMUL 4CAM

- G-Code creation is 8X faster.

Analysis for traverse motions is now improved and provides a comprehensive comparison between two available CNC machines in time and tool travel distance. This is an exclusive tool to facilitate a decision in the workshop between machines and gain optimal productivity.

- G-Code creation is 8X faster.

- NCSIMUL AUTOMATION

- In NCSIMUL Machine, Automation module runs automatically G-code validations without user interaction. It provides a go/no-go gage on CNC programs to the shop floor.

- Automation is improved with a better workflow based on XML development. The system can be set on a company server, and will process continuously job validations provided by the programming team.

- NCSIMUL NCdoc

- Dedicated to the automatic generation of datasheets in the workshop, the NCSIMUL 2018 release allows for the documentation of each operation, with more details and graphics, to improve communication and collaboration between the programmer and the shop floor. It is a smart assistant built to eliminate any possible misinterpretations.

Gilles Battier, CEO of SPRING Technologies concludes: “Our innovative technologies, our strong commitment to optimizing the value chain, our involvement in competitiveness clusters, GIFAS and other networks, places us at the core of factory of the future ecosystem, through Industry 4.0. Uses and interactions between people and machines are changing significantly. NCSIMUL anticipates these changes. NCSIMUL 2018 offers more automation and prediction of the repetitive tasks and especially for the elimination of errors, which are time-consuming for our customers. The time saved by engineers, programmers and managers, using our technologies, allows them to use their time in more productive ways at the company and make parts better, faster and cheaper.”

About SPRING Technologies

SPRING Technologies develops software solutions designed to optimize manufacturing companies’ CNC machines to reduce costs and maximize productivity.

Its product NCSIMUL® provides a complete and integrated control of the production process of Industry 4.0. It improves all the steps, since the communication between all the machines of the workshop and their monitoring, to increase their feed rate, by going through cutting tool management for cost reduction, G-code verification and optimization, for collision-free and operating cycles reduction, and finally, for one-click programming of CAD programs for a simple and fast production transfer.

This unique approach simplifies the digital chain and provides needed tools and flexibility for the implementation of automated factories.

Based in France, Germany, PR China and the USA, the company was founded in 1983 and collaborates with manufacturers in aerospace and defense, transportation, energy, industrial equipment and medical devices, using CAM software’s such as CATIA, NX, CREO, TOPSOLIDCAM, MASTERCAM and more. Through its global network of resellers, SPRING supports its customers all over the world.

NCEXPERIENCE, NCSIMUL, Optitool and NCdoc are registered trademarks of SPRING Technologies.

SPRING Technologies

50 Milk Street | 16th floor

Boston, MA 02109

P: (617) 401-2197

F: (815) 425-2197

Contact:

Asia GARCIA | SPRING Technologies Boston

agarcia@ncsimul.com