What if you could fully train someone for use on any CNC machine Siemens produces without ever having to have any hands on experience? What if you could check tolerances and specifications of a product before it was even milled? With Sinutrain, Siemens’ virtual training software for their line of CNC machines utilizing Sinumerik Operate, you can.

What if you could fully train someone for use on any CNC machine Siemens produces without ever having to have any hands on experience? What if you could check tolerances and specifications of a product before it was even milled? With Sinutrain, Siemens’ virtual training software for their line of CNC machines utilizing Sinumerik Operate, you can.

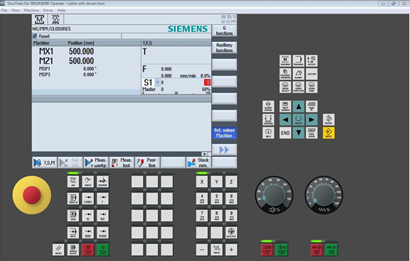

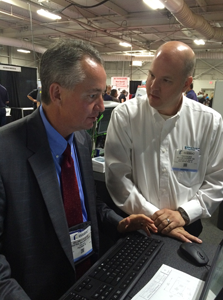

Demonstrated at the 2015 EASTEC, Sinutrain allows for an unparalleled training experience. Sinutrain’s PC based software recreates the same user interface used on all of Siemens versatile CNC controllers with Sinumerik Operate. Every function and detail you would encounter in the real world is represented digitally in the software environment. All of this is possible due to the back bone of the versatile Sinumerik Operates interface.

“Even if the machine operators have never worked with a Sinumerik CNC before they can use the complete operating and programing functions afterward, and those who have already worked with Sinumerik 840D usually pick it up right away,” describes Schmidt of Huron Graffenstaden. After the company made the Sinumerik Operate HMI their standard control option, Schmidt claims that in as little as four days, a complete novice can be fully trained.

The software environment can work directly with the company’s CAD system making it possible to not only learn the basics of CNC operation but visualize the parts being designed right on the screen. A user is able to select the stock of the part, for example, aluminum and then enter the user specified values for turning and milling. No other software gives students or even experts the ability to take the same procedures learned in the low-cost and convenient environment and apply them directly to real world applications.

Intuitively designed safety protocols warn of any user input error. When the program detects an error, transposing a measurement by a tenth of a degree for instance, Sinutrain will flag the value, allowing the operator to make the correction before moving on. Furthermore, paired with the latest version of the software, V4.5 ED.2, the same collision avoidance functions are represented in the software environment. Tool and program administration through functions such as Manage MyTools and Manage MyPrograms, features currently used in Sinumerik Integrate, are accessed in the same manner.

The versatility of Sinutrain lies far beyond the training aspect of the program. Once the design has been created in the virtual environment, that file can be then downloaded to a simple flash drive and taken to any model of Sinumerik CNC controller to produce the product exactly as it was designed in the program, whether that machine is the entry level Sinumerik 808D, the compact Sinumerik 828D or the premium, flexible, and openly designed Sinumerik 840D sl.

For more information, please visit:

www.industry.siemens.com

Or contact:

contact.cnc4you.i@siemens.com