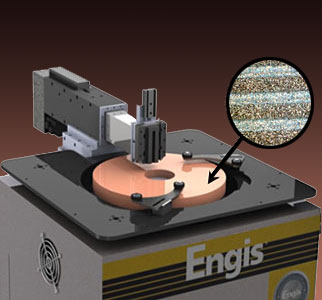

Engis Corporation’s unique FastLap Facing Device, an option for its FastLap series of lapping and polishing machines, increases plate flatness to improve precision and repeatability when manufacturing semi-conductors, optical devices, LEDs, MEMs (micro-electro-mechanical systems), precision medical components, electronics, carbides, steels and ceramics.

Highlights/Key Facts

- First-of-its-kind device uses computer-controlled diamond tool bit to recondition lapping plates for superior topography.

- Predictable and repeatable plate conditioning process delivers precision lapping results, supports quality objectives.

- FastLap Facing Device eliminates random, operator-dependent “black art” associated with standard industry method of plate conditioning.

Engis Corporation, a leading worldwide provider of superabrasive systems, has introduced its FastLap Facing Device, an optional upgrade for its FastLap series of lapping and polishing machines. Engis has globally pioneered the development of facing devices for the purpose of in-situ lapping plate preparation.

Lapping plates conditioned with the FastLap Facing Device produce more consistent surface finishes and more predictable removal rates, helping manufacturers achieve quality goals, reduce reject rates and lower overall production costs.

The FastLap Facing Device uses a diamond tool bit to remove the top (worn) layer of the lapping plate, machining it flat to within microns. To produce a controlled surface geometry and texture, the device then makes a second pass, which machines a groove pattern that serves as the basis for structured embedding of abrasive particles. Plates reconditioned with a facing device show excellent batch-to-batch surface consistency.

The costs of raw materials in lapping operations, such as sapphire for optical components or gallium nitride for semi-conductors, tend to be expensive. Further, lapping occurs at the end of the manufacturing process. A rejected part loses not just the value of the material, but all of the value-added manufacturing steps as well. As such, the predictable, repeatable and controlled results from the FastLap Facing Device can reduce total cost of operation while providing an additional quality assurance.

Click HERE to view it in action.

Links

- FastLap Facing Device (includes video of facing process)

- FastLap series of lapping and polishing machines

- Engis U.S. Sales and Distributor locator

Additional Information

Eliminating Black Art

The FastLap Facing Device must be factory-installed, and it is available on all of Engis’ FastLap lapping and polishing systems (which is the company’s most popular lapping system). FastLap systems can achieve less than .1 microinch Ra surface finish and are available in hand weight and pneumatic versions. Depending on model, FastLap machines utilize lapping plates from 15- to 48-inches and can be customized to a wide variety of applications, including the production of semi-conductors, optical devices, LEDs, MEMs (micro-electro-mechanical systems), precision medical components, electronics, carbides, steels and ceramics.

The lapping process demands excellent plate flatness to achieve consistent results. As plates become worn and uneven, they periodically require reconditioning. Until Engis developed the FastLap Facing Device, reconditioning involved using diamond-plated conditioning rings (of which Engis is a leading provider) and the experience of a highly skilled operator. Reconditioning using this method can be a demanding task that results in excessive machine downtime and production losses. The FastLap Facing Device eliminates these sources of variables, replacing them with the computer-controlled diamond tool bit.

About Engis

Engis Corporation, headquartered in Wheeling, Ill., is a leading provider of superabrasive finishing systems and HYPREZ high precision micron diamond and CBN powders. Engis solutions include grinding, honing, lapping and polishing products, as well as fully configured, custom-developed manufacturing systems. Industries served include electronics, semi-conductor, medical devices, aerospace, ceramics, mold/tool/die, automotive, mechanical valves/seals, foundries and more.

Engis Corporation

105 West Hintz Road

Wheeling, IL, 60090

800-993-6447

P: (847) 808-9400

F: (847) 808-9403

Editorial contact:

Chuck Schroeder | Insight Marketing

chucks@imipr.com or 262-240-9790.