Mazak will demonstrate several innovative machines, one of which is making its Canada debut, in booth 2500 at the 2011 Canadian Manufacturing Technology Show taking place October 17 – 20 at the Direct Energy Centre in Toronto. The machines are advanced solution ideas for various industries, such as aerospace, energy, heavy machinery equipment, valve, medical, die/mold and general job shops.

For the first time at CMTS, Mazak will showcase its INTEGREX i-300 Multi-Tasking center. Ideal for mid-size, complex part machining, Mazak’s INTEGREX i-300 Multi-Tasking center offers significant productivity improvements through B axis and C axis contouring capabilities and a combination of extreme versatility and accuracy.

Achieving and maintaininghigher accuracies are accomplished through several design features, including Mazak’s unique roller cam drive for the rotating B-axis. It features scale feedback, rigidity and no backlash while reducing friction. A powerful 12,000 rpm milling spindle is mounted in the vertical rotating B-axis with a range of -30° to +240°.

The INTEGREX i-300’s configuration features a 4,000 rpm spindle for turning with C-axis control. The machine accommodatesparts up to 25.9” in diameter and offers a 3.58” spindle bore. For a compact Multi-Tasking center, the INTEGREX i-300 boasts an impressive true Y-axis travel of 9.8” and vertical X-axis of 24.2”, with 4.92” below centerline. Plus, the machine’s 36-tool changer is conveniently front-mounted for easy access.

Also at CMTS, Mazak will show its SLANT TURN NEXUS 550M, a powerful, heavy-duty CNC turning center designed for large, long shaft-type part turning. The machine increases production in the machining of oil field pipes, pipeline control valves, turbine wheels, aircraft and off-roadparts and power generation components.

For automated part processing, the machine features Mazak’s NC servo-driven tailstock that is fully programmable and controlled through part programs for automatic accurate positioning. Further, because of its positive independent drive system, thetailstock can be used to drill holes on shaft centerlines, adding to the SLANT TURN NEXUS 550M’s job processing versatility.

The machine’s headstock features a 10.8″ bore and a 60 hp, 1,000 rpm turning spindle that generates up to 5,163 ft. lbs of torque for heavy duty metal removal. A 12-position drum turret provides rapid tool indexing, and a 10 hp, 4,000 rpm high speed milling spindle for roughing, grooving, endmilling and facemilling operations allows many processes to be completed in single machine cycles. To accommodate long shaft workpieces, the SLANT TURN NEXUS 550M’s axis travels measure 18.25″ in the X-axis and 129.88″ in the Z-axis, with a 40.7″ swing capacity and steady rest that handles diameters up to 16.14”.

CMTS attendees seeking anaffordable and versatile vertical machining center will see Mazak’s VERTICAL CENTER NEXUS 510C, the most popular and well-accepted machine of its kind in the manufacturing industry. The machine provides rugged, reliable performance and exceptionally high positioning accuracy and repeatability for a wide range of machining applications. Equipped with a CAT 40 taper, 25 hp, 12,000-rpm integral spindle/motor, the VERTICAL CENTER NEXUS 510C offers a large machining area, with X-axis travel of 41.3″, and full Y- and Z-axis ranges of 20″.

The VERTICAL CENTER NEXUS510C has a maximum table load of 2,640 lbs. and a maximum part swing of 21”. The machine’s 3 linear axes attain high-speed rapid-traverse rates of 1,417 ipm at 0.5G acceleration, and a 5.2 second chip-to-chip tool change time further slashes non-cutting time in favor of increased production. The machine is equipped with a 30-tool ATC for generous tool storage capacity.

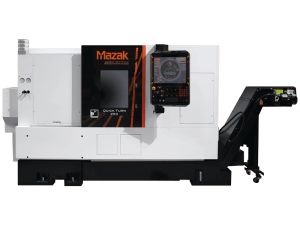

Also featured at CMTS will be Mazak’s QUICK TURN SMART 250 turning center. The machine delivers fast axis feedrates and features the user-friendly MAZATROL SMART control, making it ideal for job shops and other high production environments. Rapid feedrates on the QUICK TURN SMART 250 are 1,811 ipm in the X-axis and 1,299 ipm in the Z-axis. The machine also has X-axis ball screw pretension for high accuracy, as well as a 10-position, high-speed, non-lift drum turret for rapid tool indexing. Additionally, the machine is very reliable, particularly when set up for long runs with an automatic bar-feeder system

The QUICK TURN SMART 250’s headstock features an 10″ chuck, mounted on a 35 hp, 4,000-rpm integrated spindle motor with a 3.5” spindle bore that is optimized for machining performance. The machine’s tailstock is NC servo-driven and fully programmable, so it can be used to drill holes on a shaft centerline, further increasing the machine’s versatility.

Optimized for large part machining, Mazak’s HORIZONTAL CENTER NEXUS 8800-II at CMTS will demonstrate high-speed, high-torque performance with its 50 hp, 10,000 rpm, 50-taper advanced integral-motor spindle, standard 60-tool magazine and rapid traverse rate of 2,362 ipm. Tool capacity on the machine can be increased through incremental options to a maximum of 330, allowing for process flexibility in horizontal machining applications. The machine’s pallet size is 31.5” x 31.5”, while ample X, Y and Z axis travels measure 55.12”, 47.24” and 52.17”, respectively. Maximum workpiece diameter and height are both 59.09”.

Intelligent Machine Advanced functions found on the HORIZONTAL CENTER NEXUS 8800-II include Active Vibration Control, which effectively dampens vibration caused by rapid changes in acceleration and deceleration, leading to finer finishes and longer tool life.

About Mazak Corporation

Mazak Corporation is a leader in the design and manufacture of productivity-improving machine toolsolutions. Committed to being a partner to customers with innovative technology, its world-class facility in Florence, Kentucky recently increased its production capacity to 150 machines per month in 2011. The facility’s “Production on Demand” manufacturing concept uses the latest in machine tool technologies as part of its lean strategy. Continuous training and development of the workforce has created a “lean” culture, which has created opportunities for continuing growth in America. Mazak maintains eight Technology Centers across North America to provide local hands-on applications, service and sales support to its customers.