1. Making Industrial Systems More Secure Against Cyberattacks

The managers at manufacturing facilities know even a few minutes of downtime could result in thousands of dollars of lost profits. Although many things could cause disruptions, 2019 will likely turn into the year when companies and manufacturers will explore ways to keep machinery, sensors and other components locked down against cyberattacks.

Recently released data indicates that taking steps to safeguard against cyberattacks doesn’t always involve complex steps. That’s because recently released data about connected industrial devices showed 84 percent of respondents had at least one remotely accessible device, but more than half didn’t have feasible antivirus protections.

A separate study carried out by Kaspersky Lab indicated that 40 percent of industrial control systems (ICS) protected by the brand’s system got attacked at least once by malicious software during the first half of 2018. That indicates cyberattacks are genuine risks in 2019.

2. Increased Applications for Augmented Reality Glasses at Work

People in the marketing and app development sectors frequently use augmented reality (AR) to get people engaged. But, 2019 will likely be when they become more apparent in the industrial realm.

Augmented reality and wearables are both tapped as industrial tech trends to watch in 2019, and AR glasses incorporate both those technologies. Tesla reportedly filed a patent for AR-enabled safety glasses intended for people working in automotive factories. The details about the technology describe how overlayed information could help employees get insights about parts, material coatings and more.

Honeywell is also using an industrial AR system offering multiple features, such as allowing wearers to capture and play video footage, and search through the recorded content with their voices. The technology also gives wearers instant access to experts who can see what they do and offer insights. Geolocation features let a person signal for help and allow rescuers to find them, too.

3. Advancements in Self-Healing Materials

Factors such as age, stress and improper use could cause materials to crack. But, scientists are hard at work creating self-healing materials that could see broader usage in 2019. At Cambridge University, researchers are engineering capsules containing concrete repair materials. The idea is that a crack in the concrete causes a capsule to burst, releasing its contents and preventing the crack from getting worse.

Then, at Rutgers University, scientists are experimenting with adding fungus spores to concrete. The spores stay dormant until cracks happen. Once those separations let oxygen and water enter, the spores activate and have a patching effect on the cracks. Moreover, a Clemson University team believes it’s close to a widespread rollout for self-healing polymers that could get added to paints and coatings.

These projects are not commercially viable yet, but they are strong examples of the creative progress ahead for 2019 and beyond.

4. High-Tech Ways to Keep Workers Safer

People should expect to see even more innovative ways to increase worker safety in 2019. Although the AR solutions mentioned above often have safety components, there are other developments, too.

One is a wearable called MākuSafe, which monitors factory conditions to attempt to warn about the “near misses” that nearly become accidents. Insurance companies are particularly interested in how the technology might reduce workers’ compensation claims.

Another connected device called the Spot-r Clip attaches to a worker’s waist belt and automatically detects falls while giving employees ways to report incidents. An insurance company is currently testing the product with two other companies in a 20-month trial at a New York City work site.

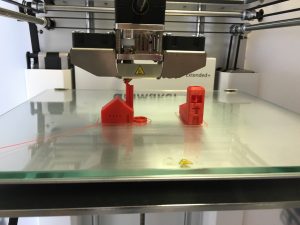

5. More Uses for 3D-Printed Parts

3D printing has substantially taken off in recent years. In 2019, companies will likely depend on it even more. One Ford Mustang model unveiled at a 2019 auto show will have 3D-printed brake parts. Also, Angel Trains, a United Kingdom rail company, will create four interior parts for its trains with 3D printing in 2019.

Depending on how those projects pan out, people in the industrial sector may realize it’s preferable to print parts instead of having them shipped from elsewhere.

6. Increased Dependence on Blockchain Technology

A recent in-depth study about how blockchain could help manufacturers revealed potential benefits ranging from reduced product recalls to increased revenues. In one IBM-backed example that’s launching a pilot in 2019, a blockchain system tracks tractors that need servicing, then measures the amount of time it takes to handle those service calls.

The blockchain logs all service-related approvals, such as schedule requests or invoicing. This use of the technology is only in Africa for now, but if things go well, it could spread to other continents.

An Exciting Year Ahead

This list highlights why 2019 should turn into an inspiring year for developments in industrial tech. Some of the solutions that break into the mainstream could forever change the ways people work.