The urgent need for workers in the manufacturing industry has been a regular topic of discussion among employers. The skills gap facing the industry is expected to result in two million jobs going unfilled, and the Community College of Denver (CCD) plans to close that gap through training programs at its state-of-the-art Advanced Manufacturing Center (AMC).

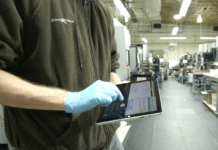

The AMC is a state-of-the-art 33,000 square-foot facility that trains new and incumbent workers in machining and welding and offers stackable certificate and degree programs. Students can earn a certificate and start working right away while continuing on towards more advanced certificates or associate’s degrees in their field.

While the need to fill these jobs is pressing, the need to find the workers is greater. The “exposure gap” is one part of the problem because today’s youth are not exposed to this industry and the potential career options that are available.

One way CCD is working to close this gap is by offering a variety of events and pathways to introduce today’s youth to these careers.

Project DIY

Two years ago, CCD introduced Project DIY to Denver area high school girls. The week-long camp introduced these girls to different aspects of the manufacturing industry including machining, welding, architecture and engineering graphics/3D printing.

In just one year the camp tripled in attendance and several of the girls repeated the camp from the previous year because they found it so beneficial. When the girls were asked if they knew the types of jobs that are possible in the manufacturing industry in a pre- and post-survey given to campers, only 36% agreed with this statement before the camp, and 91% agreed after the camp was completed.

“Project DIY changed my opinion about what I can do. We learned so much so quickly,” said Caroline Pease a senior at East High School. “It’s just incredible how much I could learn in just this one field or this one set of fields and beyond. It opened my mind about how much more I can do in the future.”

“Project DIY changed my opinion about what I can do. We learned so much so quickly,” said Caroline Pease a senior at East High School. “It’s just incredible how much I could learn in just this one field or this one set of fields and beyond. It opened my mind about how much more I can do in the future.”

Manufacturing Day

Two years ago, CCD participated in the National Association of Manufacturer’s annual Manufacturing Day event, which is a celebration of modern manufacturing meant to inspire the next generation of manufacturers.

CCD opened its doors to Denver area high school students, non-traditional students and the general public for tours of its facilities, and an opportunity to meet faculty and staff who run these programs. Students toured CCD’s Advanced Manufacturing Center, and were granted hands-on experience with a welding simulator and CNC plasma cutter.

The event concluded with a “Made in Colorado” expo to showcase area manufacturers and the products they produce. Sixteen manufacturing companies representing a variety of industries including aerospace, construction, machining, glass recycling, 3D printing and drone manufacturing showed samples of their products and talked with students about career opportunities.

“Just like Project DIY, this event gave high school students the opportunity to see first-hand the manufacturing center and experience some of the equipment. Our goal is to plant the seeds of manufacturing as a life -long career prospect in the minds of these young men and women,” said Matt Sweeney, director of CCD’s Advanced Manufacturing Center. “CCD’s primary focus is on creating pathways for these students to help them see what possibilities are available to them.”

Manufacturing Mixer Introduces Employers to Employees

Last fall, CCD also offered a Manufacturing Mixer to help connect employers and potential job candidates to employment opportunities. Eighteen area employers attended the mixer and five students accepted job offers within one week of the event. A post-survey evaluation indicated that 100% of the employers would return to the Manufacturing Mixer.

Voletha Bradley, a career coach at the Strengthening Working Families Initiative who attended the event thought it was a great success, “There was a great blend of new employers and students. I think the mixer created its own buzz and the employers were very impressed with level of preparedness in the CCD students.”

Internships Offer Hands on Education

Thanks to feedback from the employers who attended the mixer, CCD launched a new credit-bearing internship class this past spring. The three-month internship program has given four students the opportunity to gain hands-on, real time experience outside of the classroom.

“While the students get plenty of hands-on experience as part of their course-work,” said Sweeney. “Giving them the opportunity to work in an actual corporate environment goes a long way towards their job-readiness.”

CCD machining student Jeremy Shlachter is one student who started work as a paid intern at SAS Manufacturing in Englewood, CO. He loves the program and has been given the experience of putting into practice what he’s learned through his studies at CCD.

“Over the course of the 3 months the work has been a mixture of basic things like learning how to keep the machines and the building clean, but I’ve also had the opportunity to run jobs on the machines and it’s great!” said Jeremey. “I have also found the experience of working along-side long-time workers at SAS invaluable because they have been so forth coming with sharing their knowledge and expertise with me.”

Jeremey will graduate this fall with his associate’s degree in CNC Manufacturing and has his sight set on full-time employment at SAS, “I’ve been learning so much so quickly and the program has really reinforced what I’ve been taught at CCD, so I’ve had the chance to put into practice everything that I’ve been studying and it’s great!”

Jeremey will graduate this fall with his associate’s degree in CNC Manufacturing and has his sight set on full-time employment at SAS, “I’ve been learning so much so quickly and the program has really reinforced what I’ve been taught at CCD, so I’ve had the chance to put into practice everything that I’ve been studying and it’s great!”

SAS mainly works on aerospace projects and Manufacturing Manager Jeff Isaacs, who has been in the industry for over 30 years, says that the internship program is needed for the industry to help find good people to fill these jobs.

“It’s really great to have two young men who enjoy machining,” said Isaacs. “We’ve given them a pretty good amount of work to do and we have the confidence in them to get the work done. We do watch what they are doing, but they are performing 90% of the work on their own.”

According to Isaacs programs like these benefit the industry. “Manufacturing is not something everyone wants to do. You have work hard, think, get your hands dirty and not everyone wants to do that,” he said. “This is a great program and we’re pleased to be a partner with CCD.”

Advanced Workforce Training

Advanced Workforce Training

Another way that CCD is working to keep the workforce vibrant is through offering advanced training for workers already working in their field. One of these programs is a partnership with the Denver Mint. The Denver Mint offers the MCAT program which is a career ladder program built specifically for the Denver and Philadelphia Mint. The program helps their employees gain skills within their trade set and workers from the Denver Mint come to CCD’s Advanced Manufacturing Center to get training and advance their knowledge base.

“The students coming from CCD are excellent workers and I think it’s because they have a good foundation from CCD in what they’re doing,” said Mark Montoya, Certification program manager, US MINT. “The students get hands-on training and the really big benefit is when they come back to the workforce they are able to share that knowledge with their coworkers so it gives us the benefit of gaining that extra knowledge.”

Lou Martinez CCD CNC Manufacturing student and tool operator at the US MINT finds that the program allows students to obtain jobs in their field because of what it teaches.

“I have learned machine shop safety and it then it goes back to the manual lathes, something that needs to be taught because it is the basics of machining,” said Lou. “It’s taught me what I need to know and then some, and is preparing me for what’s to come in the future.”

CCD’s Machine Shop brings state-of-the-art equipment and training to our students. The machine technologies program begins with basic manual mill and lathe, print reading, and advance to 2 axis mills and lathes. Students in the machine technology certificate and Associate of Applied Science degree use 3 and 4 axis machines. Classes in CAD/CAM 3D, 5 axis milling, 6 axis dual spindle lathe and wire EDM are also available for advanced training for experienced workers, giving them a chance to enhance their skills and providing more opportunities for both employee and employer alike.

“All of these activities help CCD introduce career pathways to current and potential students, which reduces the exposure gap,” said Sweeney. “CCD’s primary goal is to provide the training students need so they can find good paying jobs. We want to create programs that are in demand and want to help our students be successful in the future and beyond.”

“All of these activities help CCD introduce career pathways to current and potential students, which reduces the exposure gap,” said Sweeney. “CCD’s primary goal is to provide the training students need so they can find good paying jobs. We want to create programs that are in demand and want to help our students be successful in the future and beyond.”

About CCD

With nearly 8,000 students, the Community College of Denver is located on the vibrant Auraria Campus in downtown Denver. As a leading point of entry to higher education for the city and county of Denver, CCD offers small-class sizes and flexible schedules, career and academic programs, award-winning professors, extensive advisory and support services, world-class facilities, easy access via RTD light rail, and affordable tuition. CCD is a federally designated Hispanic Serving Institution and is one of 13 community colleges in the Colorado Community College System (CCCS).