Manufacturers in the U.S. and across the globe understand the economic impact of the industry. The sector’s impact on economies is, and always has been, substantial. Developed, viable economies around the world demonstrate that skills, knowledge, innovation and manufacturing capability enables opportunity and advancement. After all, one thing doesn’t change: high demand for manufactured products. You’re a big part of that equation: The U.S. remains the world’s largest manufacturing economy – you produce 19 percent of all globally manufactured products.

Manufacturers in the U.S. and across the globe understand the economic impact of the industry. The sector’s impact on economies is, and always has been, substantial. Developed, viable economies around the world demonstrate that skills, knowledge, innovation and manufacturing capability enables opportunity and advancement. After all, one thing doesn’t change: high demand for manufactured products. You’re a big part of that equation: The U.S. remains the world’s largest manufacturing economy – you produce 19 percent of all globally manufactured products.

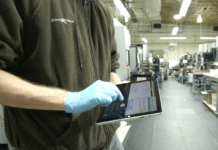

Manufacturing is in the midst of a significant revolution in new technologies, ideas and opportunities. Correspondingly, as plant floors become more advanced and demand expands across the country, employee knowledge, experience and ability are becoming increasingly critical to manufacturing’s success.

Today, companies leading business innovation are increasing investment in training and development programs to keep up-to-date with new technologies and equipment, recognizing that increased productivity, reduced waste and the abilities of skilled, knowledgeable employees directly affect the bottom line; while promiseing sustainable productivity, revenue and growth.

Studies show that talent-driven innovation, based on the quality and availability of workers (skilled labor, as well as researchers, scientists and engineers) is the number one driver of manufacturing competitiveness. In spite of this fact, finding, hiring and retaining employees with the right skills has proven to be a challenge.

Faced with the awareness and opportunity to impact that number one driver of competitiveness — the availability of skilled employees — training for new talent and those already in the existing workforce is seen as a high priority. But somehow that awareness falls short in implementation. An SME survey found that more than 80 percent of companies acknowledge a gap in the skills held by potential employees and those needed, but less than 20 percent of the companies surveyed offer a structured manufacturing training program.

In short, American manufacturers regularly invest heavily in modern plants and cutting-edge equipment and operations to maintain productivity and competitive position – but many of those same manufacturers are not investing at all in their greatest opportunity.

How Big Is the Opportunity?

Approximately 600,000 manufacturing jobs are currently unfilled because people lack the skills needed by employers. And, the skilled worker shortfall is expected to grow to 2 million by 2025 if we don’t ramp up our efforts to prepare the workforce. The industry as a whole has to invest in our most valuable asset – our current and our potential American workforce. This is your (and our national) “skills gap.”

America continues to have one of the most advanced and skilled workforces in the world, yet 89 percent of manufacturers say they are having difficulty finding qualified talent. Not only does the lack of skilled workers contribute to increased overtime and production downtime, it also impacts business growth and innovation.

America continues to have one of the most advanced and skilled workforces in the world, yet 89 percent of manufacturers say they are having difficulty finding qualified talent. Not only does the lack of skilled workers contribute to increased overtime and production downtime, it also impacts business growth and innovation.

The increased pace of technology is bringing vast changes to the industry. At no other time has technical innovation moved so quickly. While this is great news for some companies, it’s a challenge for many job shops, machine shops, maintenance repair operations and production line manufacturers. If their workers aren’t capable or can’t keep up with the rapid pace of change, they’re unable to leverage the tremendous opportunity for advancement through the adoption of those new technologies. Even as the demand for unskilled labor has decreased, the opportunity for skilled, knowledgeable employees has expanded.

A Solution – And the Opportunity

The skills gap issue is a big challenge to confront, and concerned companies are looking for resources to tackle the issue. There are actually already measures companies can take, and resources they can leverage, to drive their workforce training needs. A proven solution is to tap into local and regional educators as well as national training providers to help assess the current competency level of their workforce and determine training needs.

Apprenticeship is a proven strategy that provides a direct line to skills training and workforce expansion. Whether for new hires or incumbent employees, apprenticeships pair On-the-Job Training (OJT) hours with classroom and online instruction, supplying a talent pipeline of qualified workers for employers and industries. Employees benefit as well, as these apprentices get paid while gaining the training needed for the skilled positions that will launch them on a promising and lucrative career path. As a result, they gain a debt-free education when compared to many of their counterparts pursuing two-year and four-year college degrees.

Manufacturing has long been an OJT industry, relying on new employees to learn from more seasoned and experienced coworkers. However, in today’s advanced technology climate, a “watch what I do” training program is no longer sufficient to build a stable, reliable and safe workforce. As a result, over the years, apprenticeships have fallen off our radar as a training option for employers and haven’t kept pace with the current demands of advanced manufacturing. But with the looming skills shortage in front of us, should we take another look at developing or expanding apprenticeship efforts?

Consider:

Your current employees have skills to share: an aging workforce takes valuable skills with them when they retire. In 2015, more than 20 percent of manufacturing’s workforce was 55 years or older. As more and more of these baby boomers reach retirement age, we’re seeing an exodus of skilled workers leave their companies without a systematic way of capturing and transferring their valuable knowledge.

You need to begin today: you can’t wait for a qualified, capable employee to complete college before they start working for your company. With apprenticeships that combine related instruction with on-the-job training, employers get a highly-skilled worker, able to contribute sooner than traditional educational routes.

High-performance organizations are 4.5 times more likely to grow existing apprenticeship programs – or start one. They’ll receive $1.47 in increased productivity and greater innovation for every dollar invested in an apprentice.

Apprenticeships of yesteryear focused on time investment to instill proficiency in jobs requiring aptitude, more than careers that need technical knowledge. Today, educators and employers can tackle the technical knowledge challenge through competency-based learning models such as Tooling U-SME’s Apprenticeship Acceleration Framework.

Frameworks like these help manufacturers and educators identify the specific skills, experience and technical knowledge required to succeed in today’s advanced workplace environments. By defining specific knowledge and skill requirements that align with standard apprenticeship job functions, these frameworks allow the development of an industry-wide standard of program design, implementation and management.

Competency-based learning offers the real-world skills and experience that apprenticeships have always provided, along with applicable, focused educational content necessary to successfully complete on-the-job requirements. Advanced technologies require the need for more training hours versus just counting hours to earn journeyman status.

You’re Not Alone

Does this challenge feel daunting? Take the first steps: get help assessing the current competencies needed by your workforce and determine what proactive training you can initiate.

For small-to-medium sized manufacturers that think their company cannot afford an in-house training program, there are governments, academic institutions, and businesses in many areas of the country offering workforce development programs to help manufacturers find – and train – the skilled workers they need to continue growing their operations.

For instance, the Robert C. Byrd Institute for Advanced Flexible Manufacturing (RCBI) in West Virginia is helping local manufacturers look at innovative ways to address the national skills gap. As West Virginia’s Advanced Manufacturing Technology Center, RCBI offers a variety of general and customized training courses that include its Machinist Technology/CNC Program, which includes a college degree option, as well as its model apprenticeship programs.

RCBI’s customized programs range from a two-day blueprint reading class to a four-year apprenticeship program conducted onsite at a local manufacturer’s shop. Integrating online curriculum from Tooling U-SME is part of a blended learning approach that also includes on-the-job (OTJ) training.

RCBI works with diverse groups including Wider Opportunities for Women (WOW), and presents summer camps and participates in career and job fairs that emphasize today’s “new manufacturing” to help showcase the reality of current production lines and shop floors.

Partnering with government, nonprofit or even for-profit training organizations gives big and small manufacturers access to resources that provide structured training programs within their business framework. While smaller companies may not have the resources available to their larger counterparts, they risk losing business if they can’t find and maintain a healthy trained workforce.

It’s Your Move

To attract and retain new talent, manufacturers must commit to establishing tried and true training programs, and educators are the secret ingredient to creating apprenticeships that will produce highly skilled employees and drive competitiveness, productivity, quality, innovation and profitability.

Manufacturers who partner with regional educational institutions and training providers to establish robust programs enable themselves to improve their operation continuously, develop and leverage their full workforce potential, increase employee engagement, and efficiently and innovatively to manufacture products in their facilities.

Regardless of whether an organization is large, medium or small, most – if not all – manufacturers can benefit from establishing ongoing learning and development programs, such as apprenticeships, to prepare their workforce. Planning will take time and money; however, the payoff will be well worth the investment.