Manufacturing in America’s Heartland

Most often, the success or failure of a business may depend much on fate as it does on ingenuity, hard work, and business sense. A combination of these things has led Scotchman Industries, Inc. to becoming one of the largest manufacturers of hydraulic ironworkers in the United States.

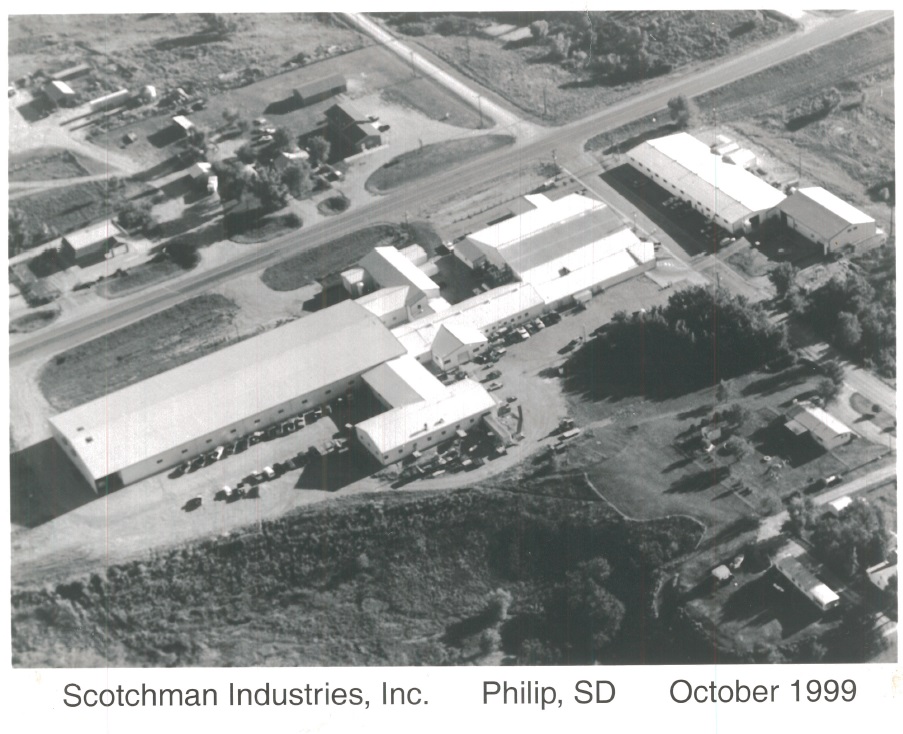

Located in Philip, a town of 880 residents situated in the middle of western South Dakota, Scotchman Industries did not start out manufacturing ironworkers, but eventually evolved into that business thanks to the determination and foresight of one man: Art Kroetch of Philip, SD.

Located in Philip, a town of 880 residents situated in the middle of western South Dakota, Scotchman Industries did not start out manufacturing ironworkers, but eventually evolved into that business thanks to the determination and foresight of one man: Art Kroetch of Philip, SD.

Art Kroetch’s roots run deep in Philip, SD. Born the oldest of five siblings on a ranch 20 miles northwest of town. He attended a rural country school until he graduated from the eighth grade. To help earn additional income for his parents, Art entered the workforce and the school of hard knocks after the eighth grade, without a formal high school or college education.

How Scotchman Got Its Name

Kroetch “settled down” in 1956 when he purchased an automobile junk yard in Philip. Junk yard dealers never throw anything away. It was this conservative characteristic in Kroetch that led him into the next phase of his business career.

Stripping old cars for his junk dealership, Kroetch found himself in the cattle oiling business by accident. Knowing in the back of his mind that those junk drive shafts could be used for something, he was reluctant to discard them and began to accumulate many in the corner of his junk yard.

At about the same time as purchasing the junk yard dealership, Kroetch went into the business of selling bulk insecticide to keep pests off cattle. Without a convenient way to apply the chemical to the cattle, Kroetch put his brain to work.

At about the same time as purchasing the junk yard dealership, Kroetch went into the business of selling bulk insecticide to keep pests off cattle. Without a convenient way to apply the chemical to the cattle, Kroetch put his brain to work.

Utilizing the stockpile of automobile drive shafts, Kroetch created a way for cattle to apply their own insecticide by rubbing against a drive shaft that was wrapped in an insecticide coated burlap. The oiler was small, did not use much of the chemical, and freed up the ranchers to do other tasks. This process was “pretty thrifty”, and so they called it Scotchman.

Kroetch, and his newly-named company, sold over 60,000 cattle oilers throughout a several state area. Cattle oilers were not the only product manufactured by Art. He made and sold portable corrals, gates, chutes and pickup stock racks. When the insecticide was discontinued by the USDA, Kroetch began to focus on the other products, which became the staples of Scotchman’s business in the early 1960s.

From Junk Business, to Metal Fabricating

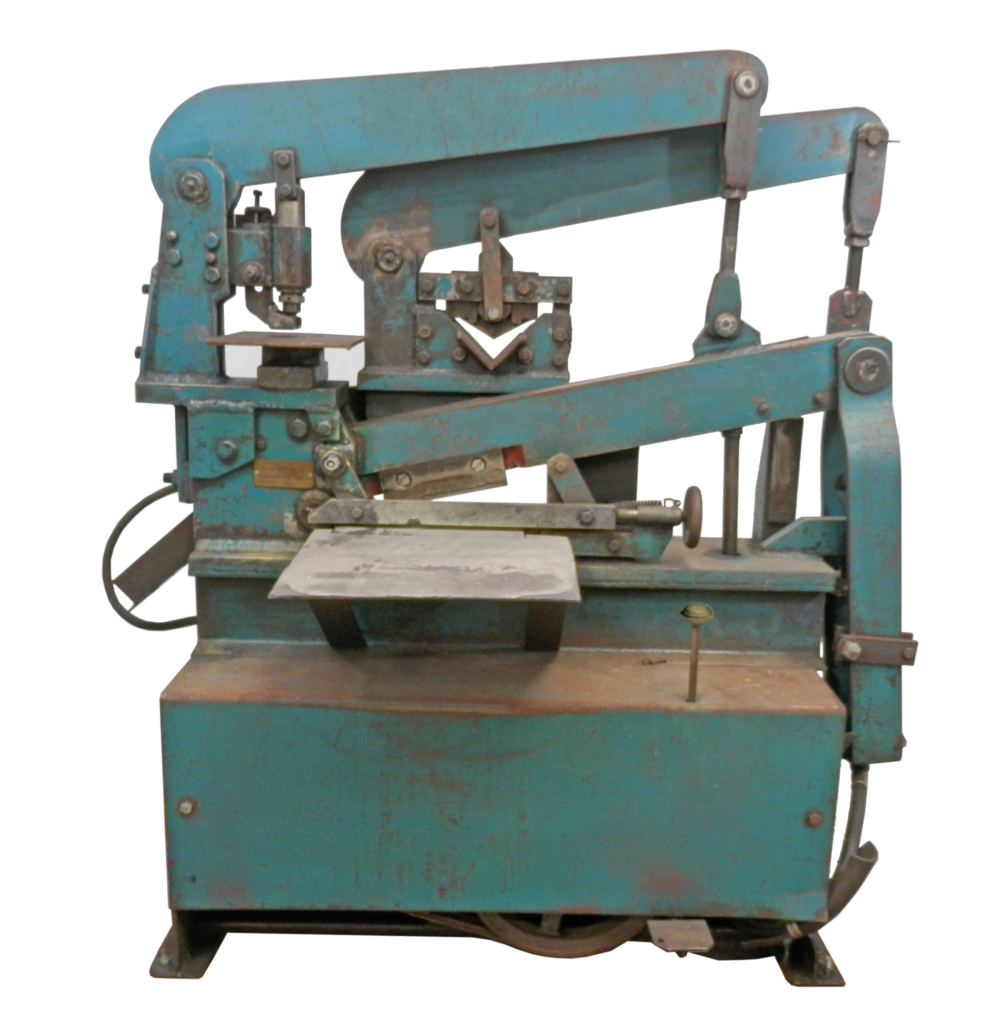

Prior to 1967, the heart and soul of the ironworking machine was the conventional flywheel-type design. Kroetch noticed an ad in the newspaper about a Minnesota man’s invention for operating ironworkers using hydraulics. Intrigued, Kroetch called the man and a price was agreed upon to purchase the patent for the invention. With the design perfected, Kroetch and six full-time employees produced the first Scotchman Industries Ironworker in 1967.

That machine would alter the course of not only Kroetch’s career, but offer steady employment opportunities for the residents of Philip. Just as the highly efficient hydraulic pressure of his machines could tailor metal to customer needs, Scotchman helped mold the small town, Kroetch held dear to his heart, into a home for many hard-working American families.

Working Iron

Working Iron

An ironworker does exactly what the name implies: it works iron. It cuts, shapes, and punches holes in cold steel by using the tremendous pressure associated with hydraulics. What started with six employees, a new product and a vision, has evolved into a manufacturing powerhouse spanning 120,000 sq. ft., employing almost eighty people and manufacturing a variety of products serving the metal fabricating industry world-wide.

The ironworker was just the beginning in product development. In 1983, Scotchman incorporated circular cold saws into its product line to compliment the ironworkers and also began distributing BEWO of Holland saws. In 1988, through a joint venture with BEWO, Scotchman began building the saws at their small factory, and in 1993 Scotchman purchased BEWO’s partnership interest. Today, Scotchman is the oldest and largest hydraulic ironworker manufacturer in the United States and the largest manufacturer of circular cold saws in North America. They also sell a line of USA made programmable measuring systems and import high-quality pipe notchers and upcut saws from Europe.

A Small Town Difference

Today, Art’s son, Jerry Kroetch, is at the center Scotchman, carrying on a tradition of proudly producing American-made machines in our nation’s heartland.

“We are proud to say that our world-famous ironworkers are still made in small town Philip, South Dakota, USA.” says Kroetch. “Our company was founded on the principle of providing well-built machinery to help manufacturers find efficient solutions for their shop needs. Nothing has changed. We focus on manufacturing quality machines that can be passed down from generation to generation.”

“Being headquartered in a small town does has its pros and cons, but the biggest benefit is our employees. Most of them are local people. The community means as much to them as the factory does.”

“Being headquartered in a small town does has its pros and cons, but the biggest benefit is our employees. Most of them are local people. The community means as much to them as the factory does.”

The town is not only small, it’s also uniquely rural. Kroetch says Philip residents drive 85 miles in any direction to find their first stoplight. Like most small towns, the residents know everybody within miles of the city limits, offering a degree of camaraderie that large cities don’t experience.

“Most of us grew up together,” Kroetch explains of Scotchman’s employees. “They take a tremendous amount of pride in what they do and in doing it well. It is that small-town family aspect that makes Scotchman thrive on a day-to-day basis.”

From the beginning, Scotchman’s business plan was based on manufacturing quality products and providing excellent customer support.

“That could not have been achieved without the support and dedication of our excellent team,” Kroetch went on to say. “Every person here plays an important role in the development of our company. Our employees continue to go above and beyond every day to ensure our products meet quality standards and to provide unparalleled support to our customers. We remain indebted to the contributions of our employees. Good employees are the foundation of great companies.”

In addition to Scotchman’s workforce, the partnerships and relationships built and maintained by the company’s global network of distributors are second to none. Scotchman’s territory representatives and distributors represent the company to the world. They strive to offer the same level of expertise and support on which Scotchman has built its reputation.

A Legacy Left

A Legacy Left

Art left a legacy, in business and in life, and inspired many to believe in the American dream with hard work and remaining steadfast in their faith. In the lobby of the Scotchman Ind. manufacturing plant, there is a Scotchman ironworker model 5014-CM covered in signatures. This was the last machine built on July 3, 2007, the day Art Kroetch passed, the hundreds of signatures decorate the never-before-used ironworker, each one a cherished name of a life Art touched.

On that July day, in an extraordinary act of love and gratitude for the man who had built and led their company for fifty years, the employees of Scotchman banded together, donating their vacation time to purchase that Ironworker in tribute to Art Kroetch. This act of love was reflective of Art’s own generous nature and kind spirit.

“It just happened to be the last machine built at the end of the day on the day he passed away,” said Jerry Kroetch, Art’s son and the President of Scotchman Industries. He said the powerful gesture was incredibly special to all of Art’s family.

“His family and employees came first,” Jerry said. “He treated all of his employees with the same respect that he wanted in return.”

A Year to Remember

2017 also marks ten years since the founder of Scotchman passed away. He was a visionary and an incredible man, husband, father, grandfather and friend to many. The remarkable success of Scotchman Industries enjoys today must be largely attributed to the aggressiveness, determination, and hard work of Art Kroetch and his ability to instill these qualities in his employees. The 5014CM that proudly stands in the Philip lobby, is just one reminder of the man who paved the way for Scotchman.

It’s been 50 years since Scotchman debuted its hydraulic-powered ironworker and they are honored to have served the manufacturing industry in America and abroad over the last half century. Although 50 years have passed since Arthur A. Kroetch founded the company, Scotchman has remained committed to their building high-quality dependable products and believing in the strength of American manufacturing.