42 Danish robots create growth and 50 new jobs

For years, Trelleborg Sealing Solutions researched the market in vain, trying to find a robot suitable for their production needs. Universal Robots turned out to be the solution they were looking for. Up until then, Trelleborg had no robots involved in its annual production of millions of products. But when the solution was found, things really took off. In 2.5 years, the factory has installed 38 UR5 robots and 4 UR10 robots followed by swift gains in productivity; orders have risen so sharply that 50 new employees were needed at the factory in Helsingør, Denmark despite the arrival of the new robot colleagues.

It was time that Trelleborg Sealing Solutions found an effective way to optimize production; Customers were demanding lower prices, higher quality and faster delivery, global competitors were gaining on Trelleborg in market share, while Trelleborg’s own factories in lower wage countries also presented a challenge to the Danish manufacturer.

The Production Manager at Trelleborg in Helsingør, Jesper Riis, is relieved to have finally found a suitable automation solution for the factory’s production of seals in high-tech plastic materials. The advanced seals are often used in high-performance equipment in cars and aircraft as well as many other industrial contexts.

‘For 10-15 years, we researched the market for suitable robots, but every single one we looked at required safety shielding. It made them unattractive for us, since we are unable to extend the actual production area at our factory in Denmark’, says Jesper Riis.

‘For 10-15 years, we researched the market for suitable robots, but every single one we looked at required safety shielding. It made them unattractive for us, since we are unable to extend the actual production area at our factory in Denmark’, says Jesper Riis.

The challenge was not made any easier by the fact that Trelleborg for some years now has been undergoing a major modernization of its machinery. Older machinery and turning machines are being replaced by modern CNC machines, which enhance the quality of the finished items and also improve speed.

Minimal space advantage:

Minimal space advantage:

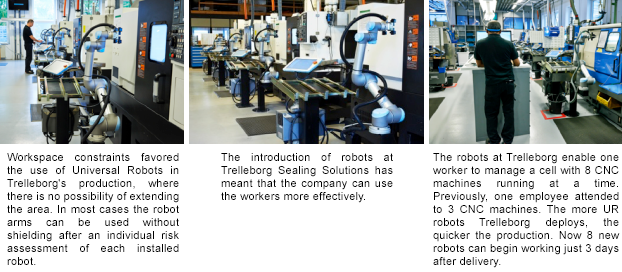

‘Because the CNC machines take up far more cubic metres of space than an old-fashioned turning machine, very flexible and small robots were needed to automate the attendance of these machines. The robot arms from Universal Robots were the only ones which would fit because, based on a thorough risk assessment, they were in most cases allowed to run without safety shielding. So now we purchase a UR-robot for each new CNC machine we buy’, says Jesper Riis.

Globally, 80% of all UR robots in industry have been risk-assessed for operation without shielding. At Trelleborg Sealing Solutions, all 42 UR robots operate unshielded. Many of the CNC machines which process seals now typically operate unattended for about an hour or as long as there are items left on the racks.

Short ROI was a requirement:

Most of the robots are fitted with a gripping hand from Schunk. All UR robots are delivered and integrated by KJV A/S and CNC.dk, which are respectively the distributor and integrator of Universal Robots in Denmark.

The Danish lightweight robots have been a part of the workforce at Trelleborg since 2012 operating on continuous shifts. The Trelleborg Group has a target of a maximum of 1.5 years’ payback on new investments. The robots deliver this: they have, on average, paid themselves back in a year and a half.

Hello to the new ‘colleagues’:

Just as new key employees in a company are often introduced to the staff on Day 1, the management in Trelleborg felt it was essential, for the success of the project, that the 330 employees should be involved in the plans well in advance. They were therefore introduced to the coming robot colleagues – or cobots, as they are also known.

‘We wanted to show them that the robot is a helpful colleague, not a competitor. It can help to make their work less stressful and more interesting, while also ensuring that they have a job with our company in the future ’, says Jesper Riis.

At a staff event, employees were invited to program a UR-robot. Annette Jensen from Trelleborg’s food service team volunteered, and she excelled by programming a UR5 to stir a pot. It took her a few minutes to do so, making a big impression on the rest of the staff that now has embraced the technology.. The robots have made the job more varied and interesting and help to create greater job security due to the positive impact automation has had on sales.

A fascinating paradox:

A fascinating paradox:

The robots at Trelleborg enable one worker to keep a cell with 8 CNC machines running at a time. Previously, one employee attended to 3 CNC machines. As a result, Trelleborg has saved 1.5 employees per cell per shift. But no employees were fired during the period due to automation. Quite the contrary. The robots are creating more jobs, because new orders are now coming in at a conspicuous rate: a total of 36,000 orders are now being placed with Trelleborg annually. The orders range anywhere from 1 unit to series of several million. And Trelleborg has taken on 50 new employees within the last two years, increasing the number of employees to approximately 330.

‘We use our machines much better with robots, and our products have never been more uniform. Basically, this means that we have become competitive and that our turnover and earnings are increasing, especially as far as large series are concerned. It’s been tough to get so many robots into operation in 2.5 years. But it has also been fun and exciting and given us a tremendous boost because everything clicked so well. Now things have become so routine that it just takes us and the integrator 3 days to install a new cell with eight new robots and put them into production ’, says Head of Production Technology, Henrik Tørnes.

Always have a ‘job-seeking’ robot:

Trelleborg Sealing Solutions keep a new robot available in their machine-building department, which the employees can experiment with to find the next automation task.

When the task for the robot is found, it is implemented and Trelleborg Sealing Solutions purchases a new ‘job-seeking’ robot.

‘Even the way of thinking in the company has changed, so now we think a robot into wherever there are opportunities to optimize with the help of automation’, concludes Production Manager Jesper Riis.

Facts about Trelleborg Sealing Solutions:

Trelleborg’s robots are supplied by CNC.dk and KJV A/S, which are the integrator and distributor respectively of UR robots in Denmark. The company’s Danish factory was founded in 1965 in Helsingør, where there are 330 employees. The factory in Helsingør had a turnover in 2013 of 380 million DKK ($70M).

Trelleborg Sealing Solutions is part of the global Trelleborg Group, which is represented in 40 countries, employs a total of 15,500 people and has an annual turnover of 17.4 billion DKK ($3.2B). The Group’s parent company is located in Sweden.

ROI:

Payback period: 1.5 years

For more information, please visit:

www.universal-robots.com

Or Contact:

sales@universal-robots.com