Hardinge Inc. (Elmira, NY) manufactures workholding products to grip parts to be turned, milled, ground, welded, assembled or positioned in the small-to-medium parts machining industry. Hardinge has completed over 200,000 custom workholding designs, while offering over 40,000 standard products. Their group of workholding engineers has over 300 years of combined experience in designing solutions to help you be more profitable.

Workholding Engineers will be on hand at booth S-8148 to discuss your gripping problems and Hardinge capabilities. This is your opportunity to meet Matt Roberts, Hardinge’s Workholding Engineering Manager, and to get to know how Hardinge can help with your gripping dilemmas, while viewing some of their custom products. They encourage you to bring your part prints and machine information.

Workholding Engineers will be on hand at booth S-8148 to discuss your gripping problems and Hardinge capabilities. This is your opportunity to meet Matt Roberts, Hardinge’s Workholding Engineering Manager, and to get to know how Hardinge can help with your gripping dilemmas, while viewing some of their custom products. They encourage you to bring your part prints and machine information.

Reasons for using Custom Workholding products:

1. Increase precision and accuracy of the workpiece

2. Reduce job setup, changeover time & operator handling

3. Eliminate second operations

4. Minimize expensive, bulky fixturing

5. Add flexibility to the machine

6. Solve gripping problems

7. Integrate automation

8. Reduce workload of your own engineering staff

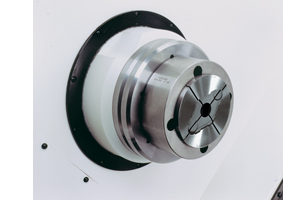

Common gripping problems involve odd shapes (like gripping a deodorant container in the Hardinge step chuck shown), part slippage, thin and delicate materials, scratching, threading, or lack of gripping surface. Before sinking hours into experimenting and creating a pile of scrap metal, the logical fail-safe move would be to put these frustrating gripping problems in the hands of experts, where the end result will be safe, accurate and reliable. “Customers have admitted that they’ve tried to manufacture custom gripping devices themselves, say Matt, and later realized that they’ve compromised the part quality and/or they’ve created a situation with added setup and changeover time.”

Now might be a good time to take a second look at your questionable gripping methods and talk to the experts at IMTS booth S-8148. For immediate assistance, drawings and sample parts can be sent to Hardinge Inc., One Hardinge Drive, Elmira, New York 14902; emailed to orders@hardinge.com; or faxed to 607-737-0090.

About Hardinge Inc.

Hardinge is a global designer, manufacturer and distributor of machine tools, specializing in SUPER- PRECISION(TM) and precision CNC Lathes, high performance Machining Centers, high-end cylindrical and jig Grinding Machines, and technologically advanced Workholding & Rotary Products. The Company’s products are distributed to most of the industrialized markets around the world with approximately 74% of the 2011 sales outside of North America. Hardinge has a very diverse international customer base and serves a wide variety of end-user markets. This customer base includes metalworking manufacturers which make parts for a variety of industries, as well as a wide range of end users in the aerospace, agricultural, transportation, basic consumer goods, communications and electronics, construction, defense, energy, pharmaceutical and medical equipment, and recreation industries, among others. The Company has manufacturing operations in the United States, Switzerland, Taiwan, and China. Hardinge’s common stock trades on NASDAQ Global Select Market under the symbol, “HDNG.”

For more information, please visit:

www.hardinge.com

Or contact:

info@hardinge.com

800-843-8801