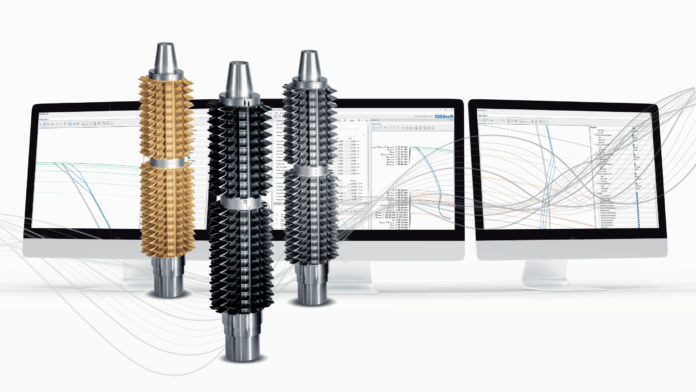

The new Hobbing module supports defining parameters, including feed rate and cutting speed. It provides a design for a time-optimized hob and the geometry of the gashes. Possible collisions between the tool and the workpiece are visualized in a graphical representation of the hobbing curve and interference contours. Chip thickness and feed marks are determined for the selected parameters.

The service life of the hobbing cutter is derived from the calculated usable tooth length and the tool life in meters. In conjunction with the costs for the hob and the resharpening, the costs per gear are determined. The cutting time and total duration are calculated using the process kinematics.

With the new Rollout calculation and corresponding graphics, KISSsoft provides a precise analysis of cylindrical gear geometry when pre- and final machining are combined. It allows users to check tip and root form diameters, including tolerance evaluation. Tolerances for both workpiece tooth thickness and machining stock can be defined according to industry standards or customized to exact project requirements.

Thanks to the evaluation for minimal, maximal, and user-defined stock, you can assess how cutter tolerances influence the final tooth form. Key parameters such as dFa, dFf, and maximum undercut are calculated to ensure proper meshing.

KISSsoft also offers flexible data input options:

- Define hobs in the “Reference Profile“ tab.

- Check tolerances (mean, min, max) in the “Rollout“ tab using predefined standards or custom values.

- Adjust gear tolerances as needed.